This is an old revision of the document!

Table of Contents

Casting electronics in resin

The Plan

I wanted to run a medium-duration test of the electrically-complete blinker before going through all the trouble and expense of encasing it in aluminium and glass. I decided to cast the electronics in transparent resin. This would be reasonably mechanically and chemically robust, but it would degrade in sunlight over a few years, turning yellow and crumbling. This would give me a test good enough to check for any drastic short-term problems with the electronics.

The Results

Success

I bought this resin from bunnings. It's a styrene/polyester resin with a MEK catalyst.

I cut out a cardboard box on the laser cutter and lined it with gladwrap.

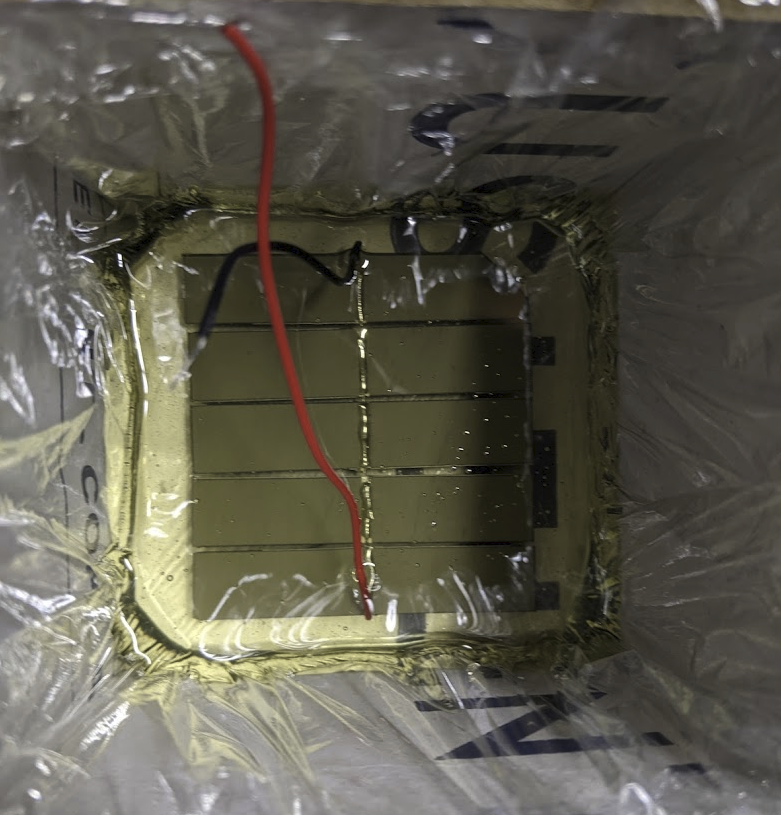

Solar cell invested.

Not too bad!

I was reasonably happy with this result. There is some white discolouration on the solar cells visible in that photo. That discolouration did not exist when I took the panel out of the mould. It formed shortly after I put it in the sun for this test. It seems to have been formed by some combination of:

- UV radiation,

- Heat,

- Resin,

- Flux, and/or

- Solder.

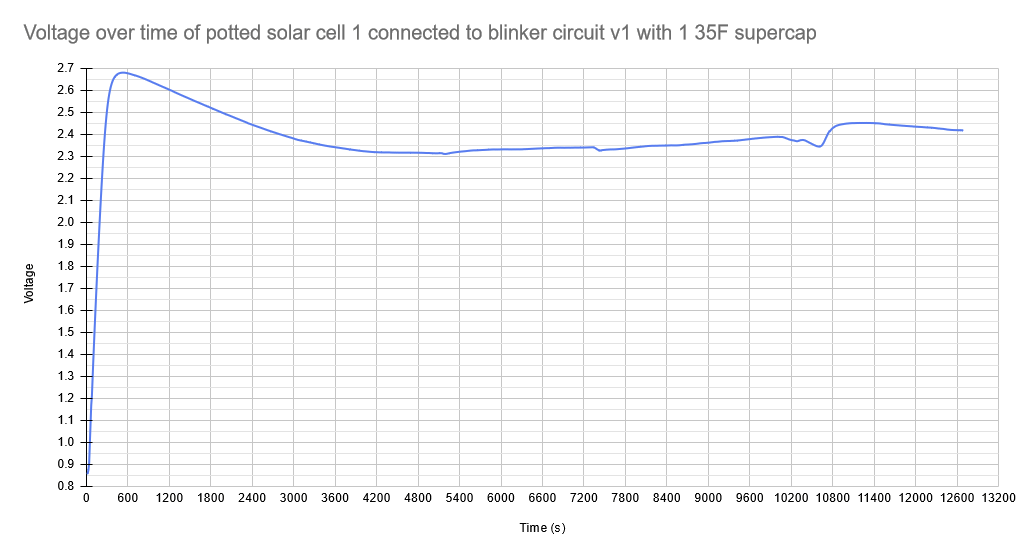

In direct sunlight this panel generates 3.1V open circuit voltage, 190mA closed circuit current. That was about double the current I was anticipating. This caused me mild concern as the voltage limiting zener might not be able to keep the voltage down. I could add more in parallel to pass more overvoltage current, but that would increase the passive energy loss in the system considerably.

I soldered it to a blinker circuit and put it in the sun:

Awesome!

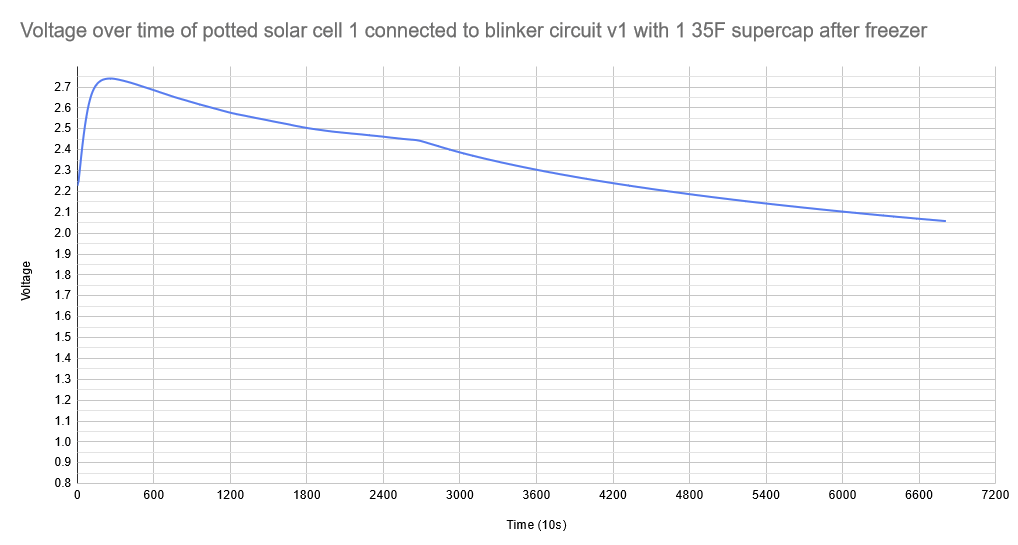

I was puzzling over why the voltage dropped off so quickly. I wanted to check whether it was panel degradation related to the discolouration or due to the panel heating up inside a pretty good thermal insulator. I put the whole shebang in the freezer for a while to see if that had any effect.

This seemed to indicate that the voltage limit was related to the temperature of the panel. Part of the way through this test the panel fell into shade, probably at the inflection point at 2710 seconds.