This is an old revision of the document!

Table of Contents

Casting electronics in resin

The Plan

I wanted to run a medium-duration test of the electrically-complete blinker before going through all the trouble and expense of encasing it in aluminium and glass. I decided to cast the electronics in transparent resin. This would be reasonably mechanically and chemically robust, but it would degrade in sunlight over a few years, turning yellow and crumbling. This would give me a test good enough to check for any drastic short-term problems with the electronics.

The Results

Success

I bought this resin from bunnings. It's a styrene/polyester resin with a MEK catalyst.

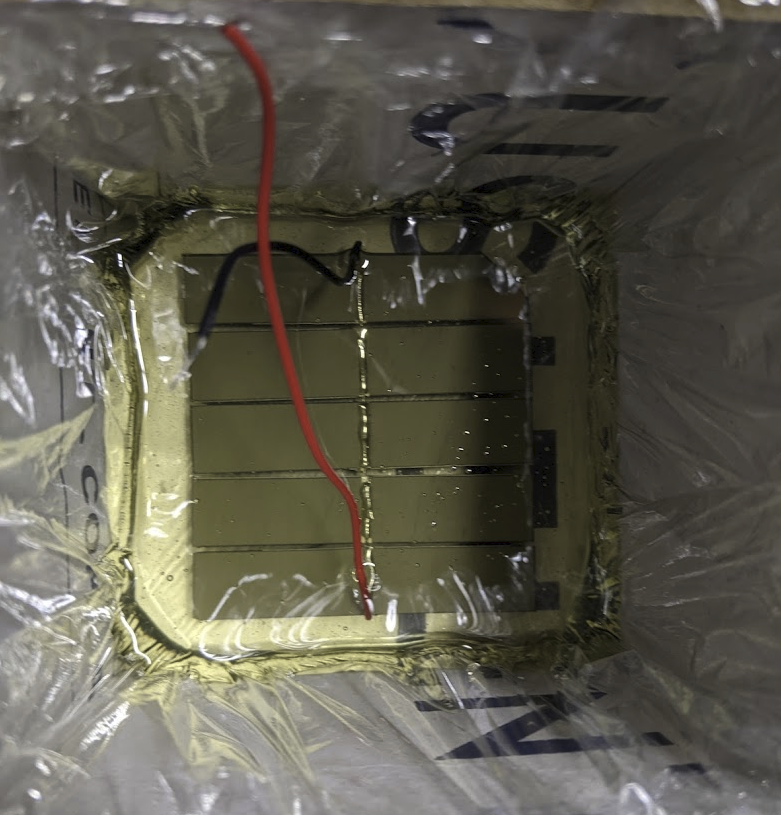

I cut out a cardboard box on the laser cutter and lined it with gladwrap.

Solar cell invested.

Not too bad!

I was reasonably happy with this result. There is some white discolouration on the solar cells visible in that photo. That discolouration did not exist when I took the panel out of the mould. It formed shortly after I put it in the sun for this test. It seems to have been formed by some combination of:

- UV radiation,

- Heat,

- Resin,

- Flux, and/or

- Solder.

In direct sunlight this panel generates 3.1V open circuit voltage, 190mA closed circuit current.

I soldered it to a blinker circuit