This is an old revision of the document!

Table of Contents

The window

The Plan

My initial plan for the window is:

- Cut a few circles out of some float glass,

- Clean them thoroughly with IPA and HCL,

- Build a stack of them to the desired thickness,

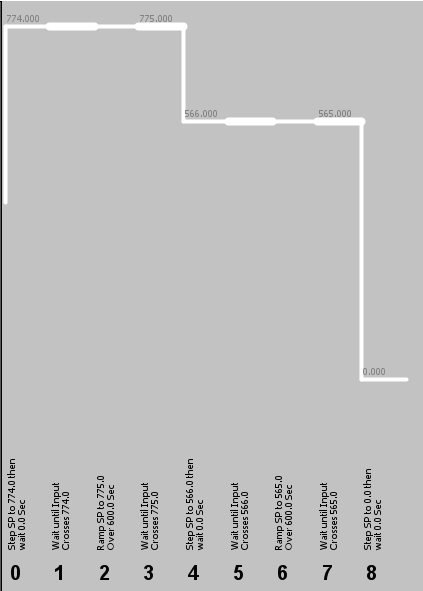

- Fire in kiln:

- Slow ramp to 775°C,

- Hold for five minutes,

- Fast ramp down to 565°C,

- Hold for 10 min,

- Slow ramp down to room temperature.

- Polish,

- Harden in a 400°C bath of potassium nitrate.

I had good success tempering bottle glass with a 560°C soak in the glass sphere project. This superb reference suggests that 565°C is a good tempering temperature for float glass, and 775°C is a good fusing temperature.

The Doing

Cutting out circles of glass.

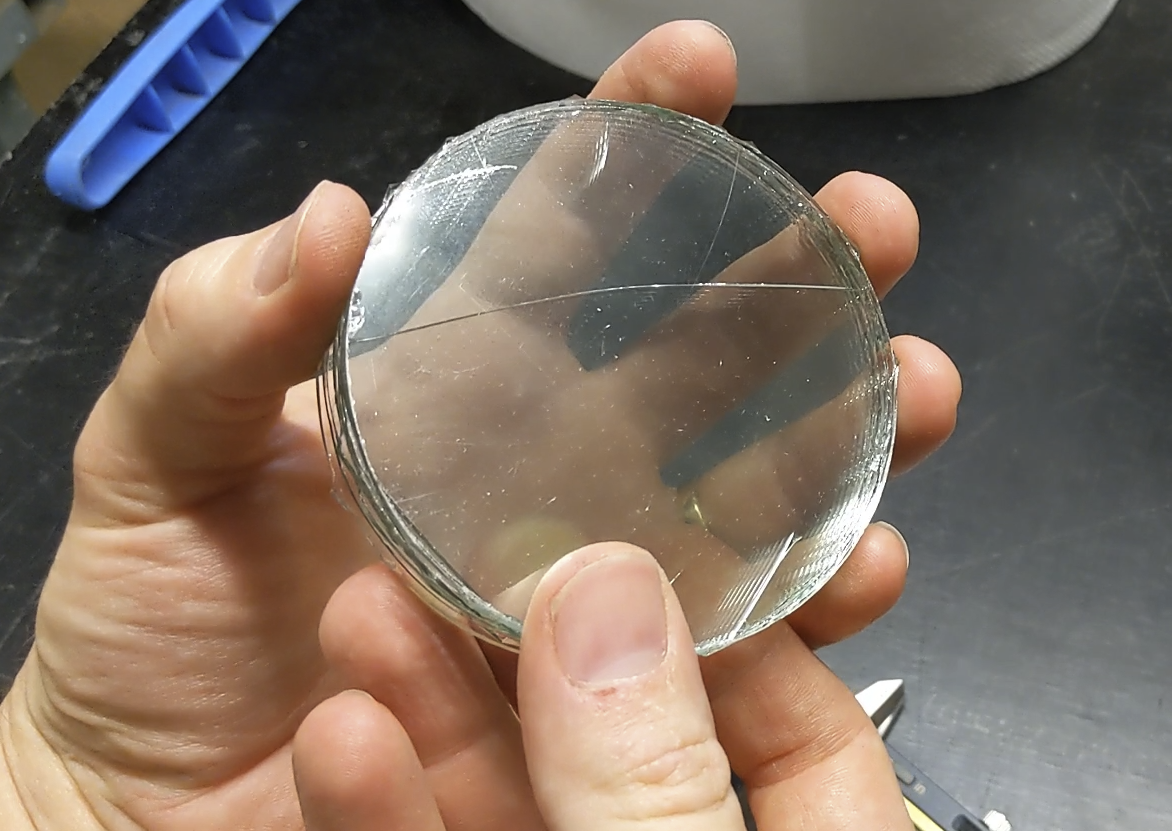

Stack of circles. There are some cracks, but they'll reform during the firing.

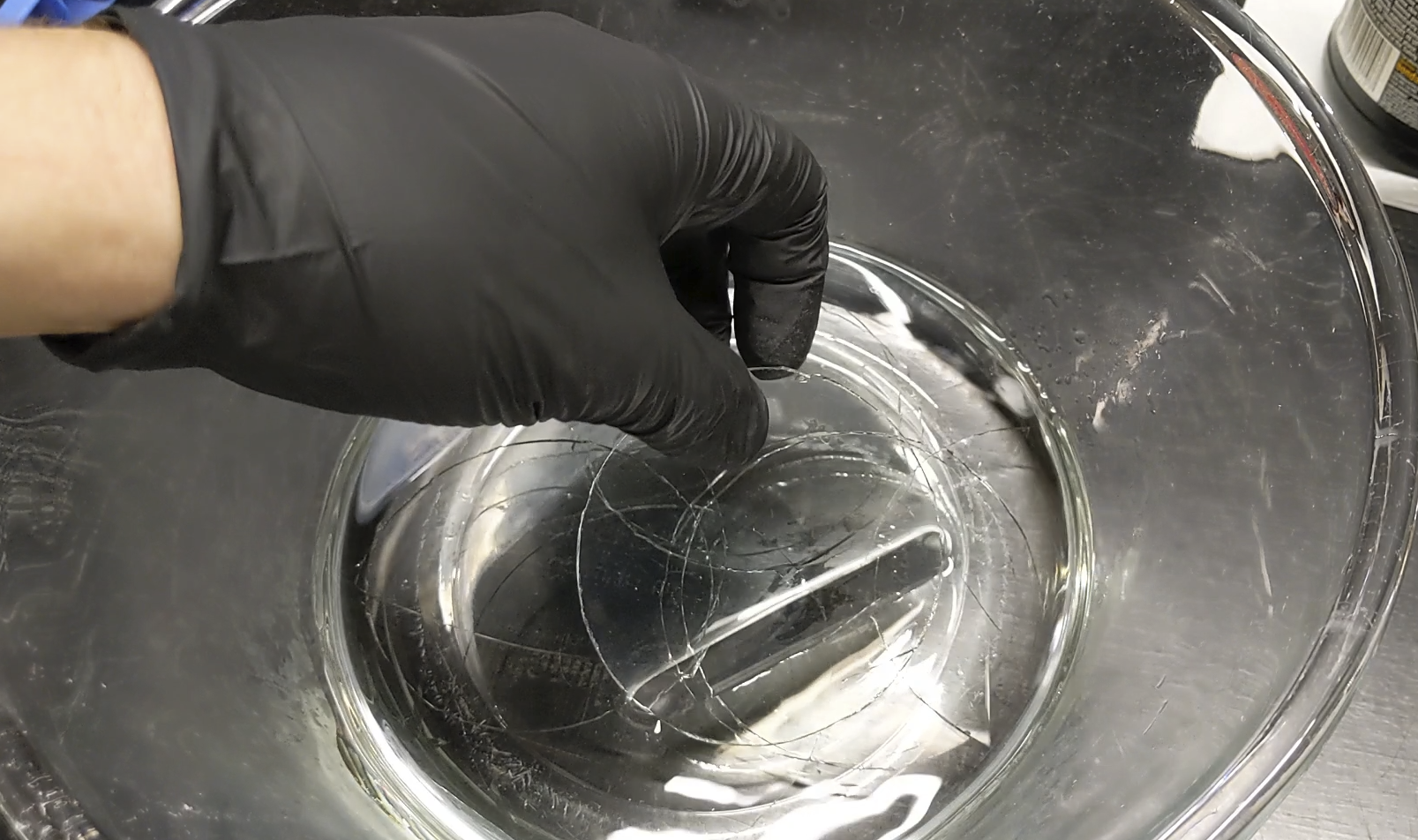

Soaking the circles in 320G/L HCL acid.

Programming up the curve in my furnace. I don't understand this software very well.

Stacked up, ready for firing.

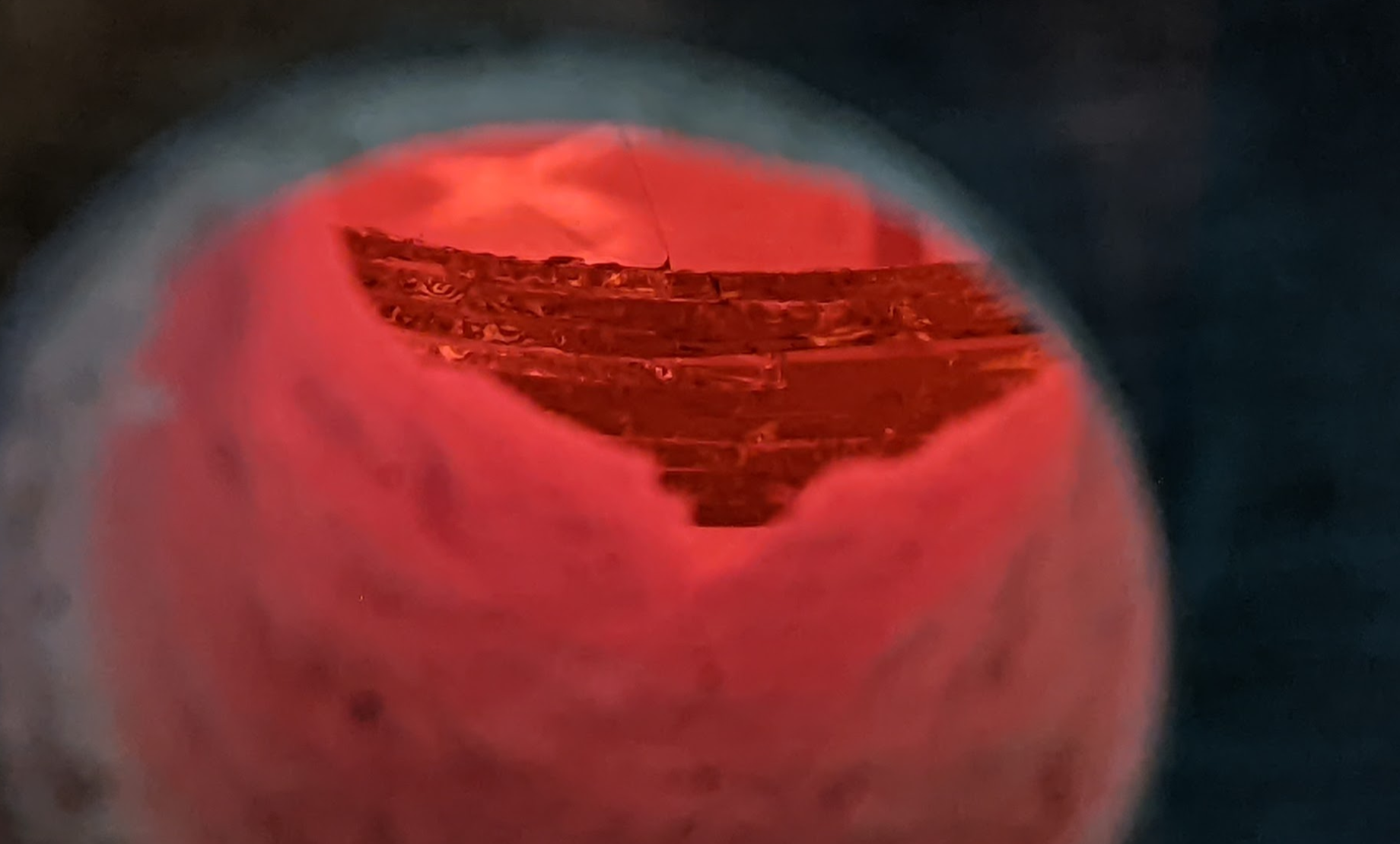

Some of the glass broke during the warm-up, and spat part of a circle out of the stack. I was able to nudge it back into position with a metal rod. I think a slower warm-up ramp would be a good idea.

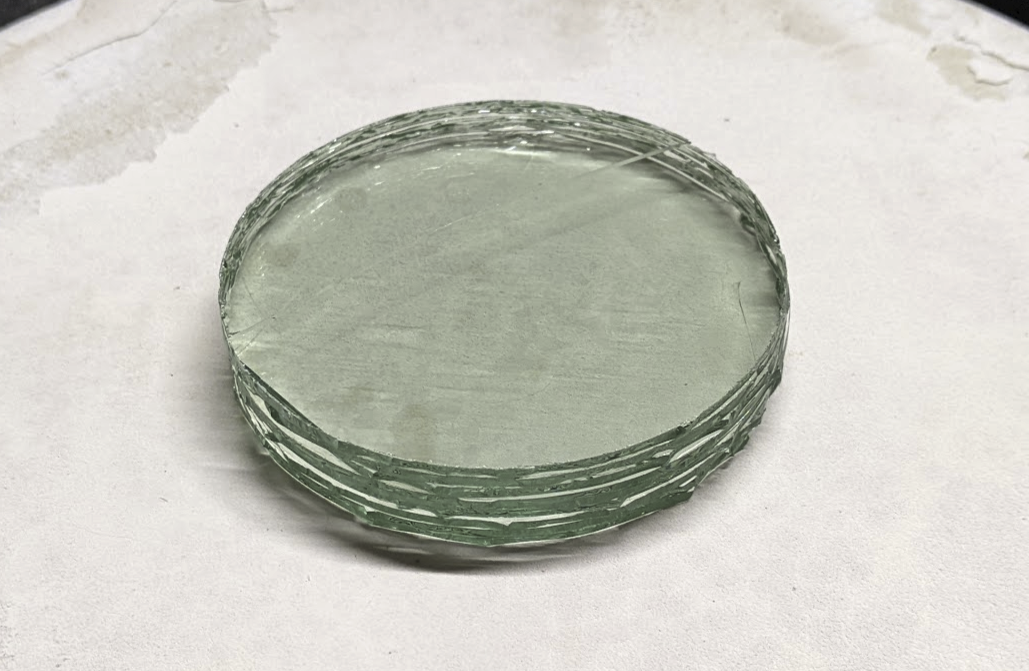

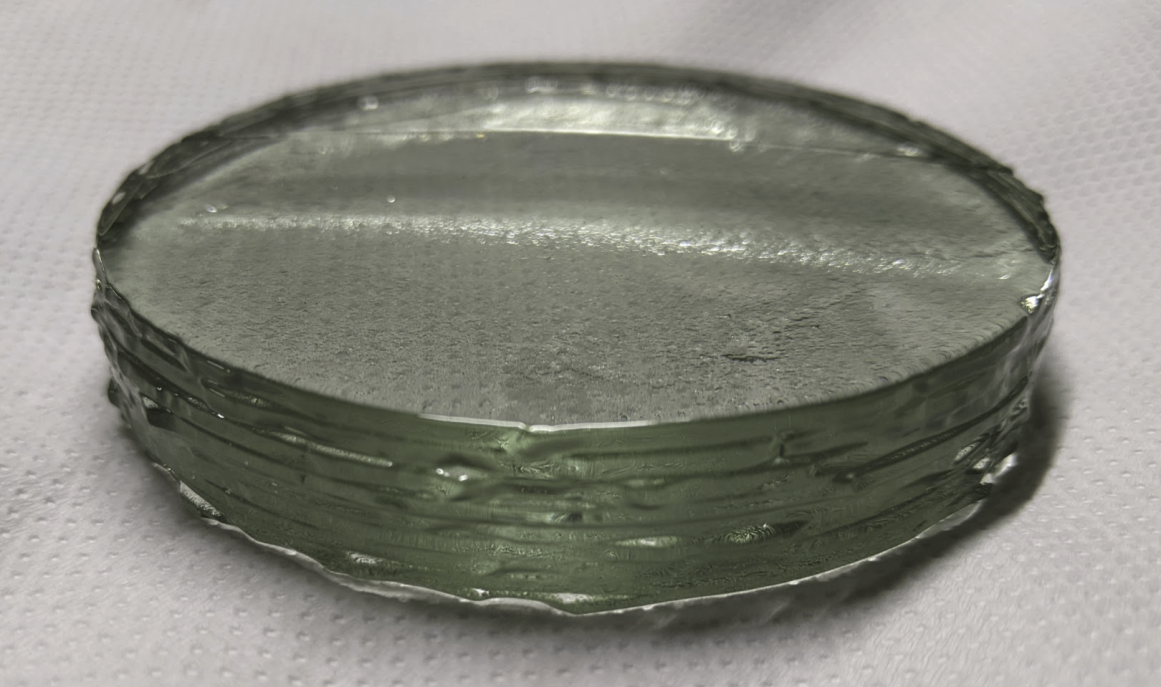

After firing. Clarity is good. I can see some air trapped between the layers, and some other general gunk stuck in there. I think I need to use distilled water to wash after the acid bath. The cracks did not fully amalgamate, and I suspect some of the layers did not properly bond together. I might try increasing the max temperature. I have done a few experimental drops and general rough handling and it shows no sign of damage. I haven't been brave enough to drop it onto concrete or anything.