Table of Contents

What I want to accomplish

- Make some glass slugs for testing polishing processes

What I've done

I want to test a few different ways of polishing glass to a high finish. For these tests I need lots of identical glass slugs. Some bad luck and poor planning when making ginger beer resulted in a good quantity of broken glass bottles.

I crushed them up into chunks no larger than about 40mm in any dimension. I then washed and sieved the glass to remove dirt, dust, and very fine glass powder.

I dried the wet crushed glass in a pot on a hotplate. I weighed out six 145g quantities of glass into a muffin pan and melted it in my furnace.

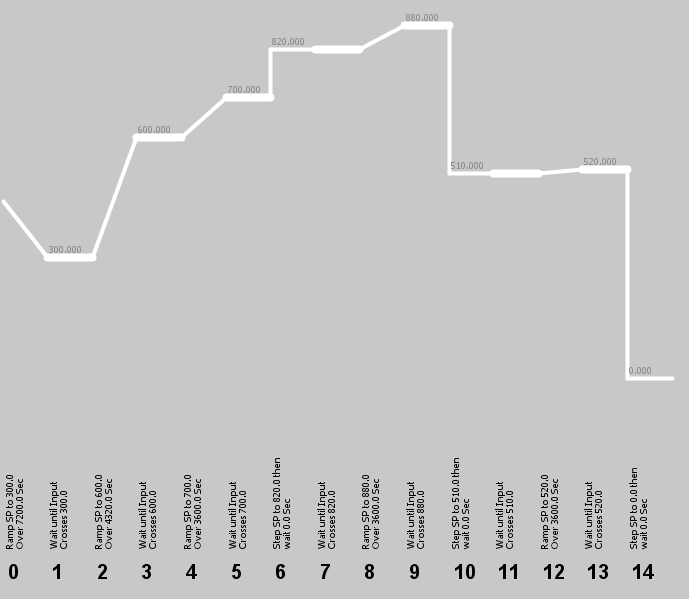

Meets:

After I started that profile running I realised I'd forgotten to paint the muffin tin in release agent. This could be bad.

Results:

Looks promising…

But no. I had to destroy the muffin tin and peel the steel off the glass in strips.

I suspect the coating on the muffin tin decomposed at high temperatures and bubbled gas through my slugs. I threw one on the linisher to see whether it would be workable for testing polishing techniques, but the bubbles are very close to the surface and I broke through almost immediately. This results in glass fragments getting caught between the polishing surfaces and gouging around.

Next time I will try to buy an uncoated stainless steel muffin tin, or I will pre-fire the tin on a dry run to burn off any coatings, then add a layer of release agent.

Video

What I want to accomplish next time

- Pre-fire the muffin tin to avoid bubbling.