Table of Contents

What I want to accomplish

- Make some glass slugs for testing polishing processes

What I've done

I bought another muffin pan and pre-fired it. This destroyed it. I think the oxide layers that formed were thicker than the metal in the pan. It had the consistency of a Sao biscuit.

I ordered a set of four stainless steel drinking cups from ebay. I pre-fired them. There was lots of black gunk on the outside afterwards, but I scrubbed it off with a wire brush, and then scoured with sand. They were still black, but without loose contaminants. They kept their strength.

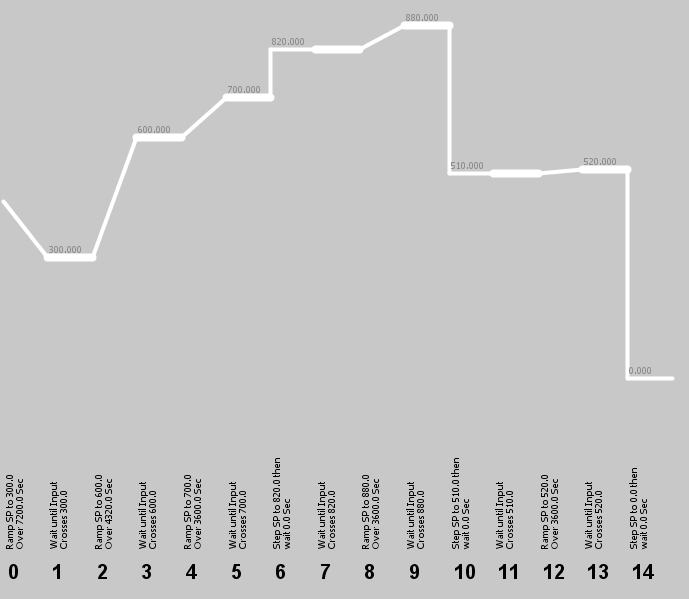

I applied a single layer of batwash and dried them on a hotplate. I measured out 130g of crushed glass into each of the four cups and ran them through the same profile as last time:

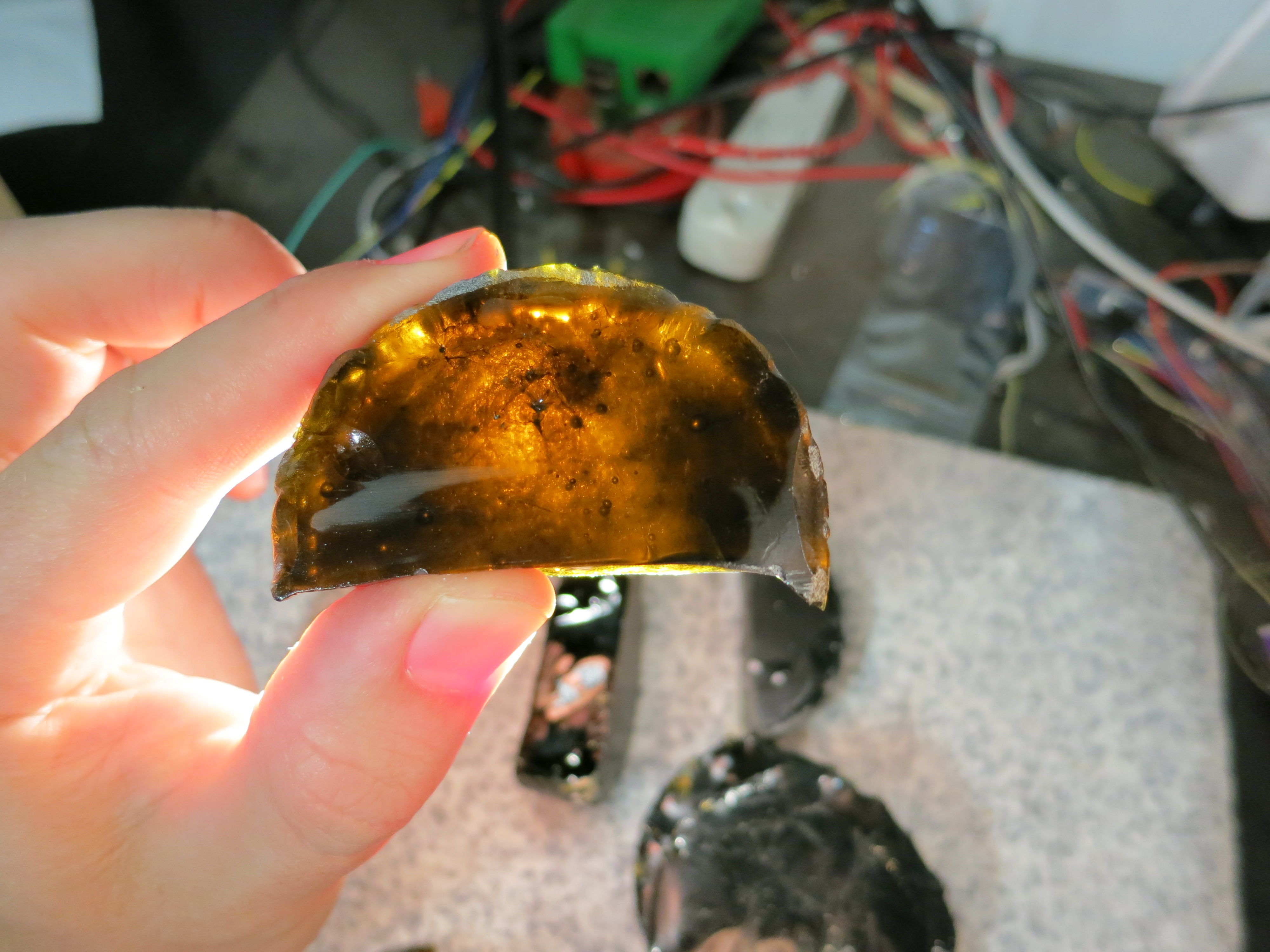

Initial results were promising.

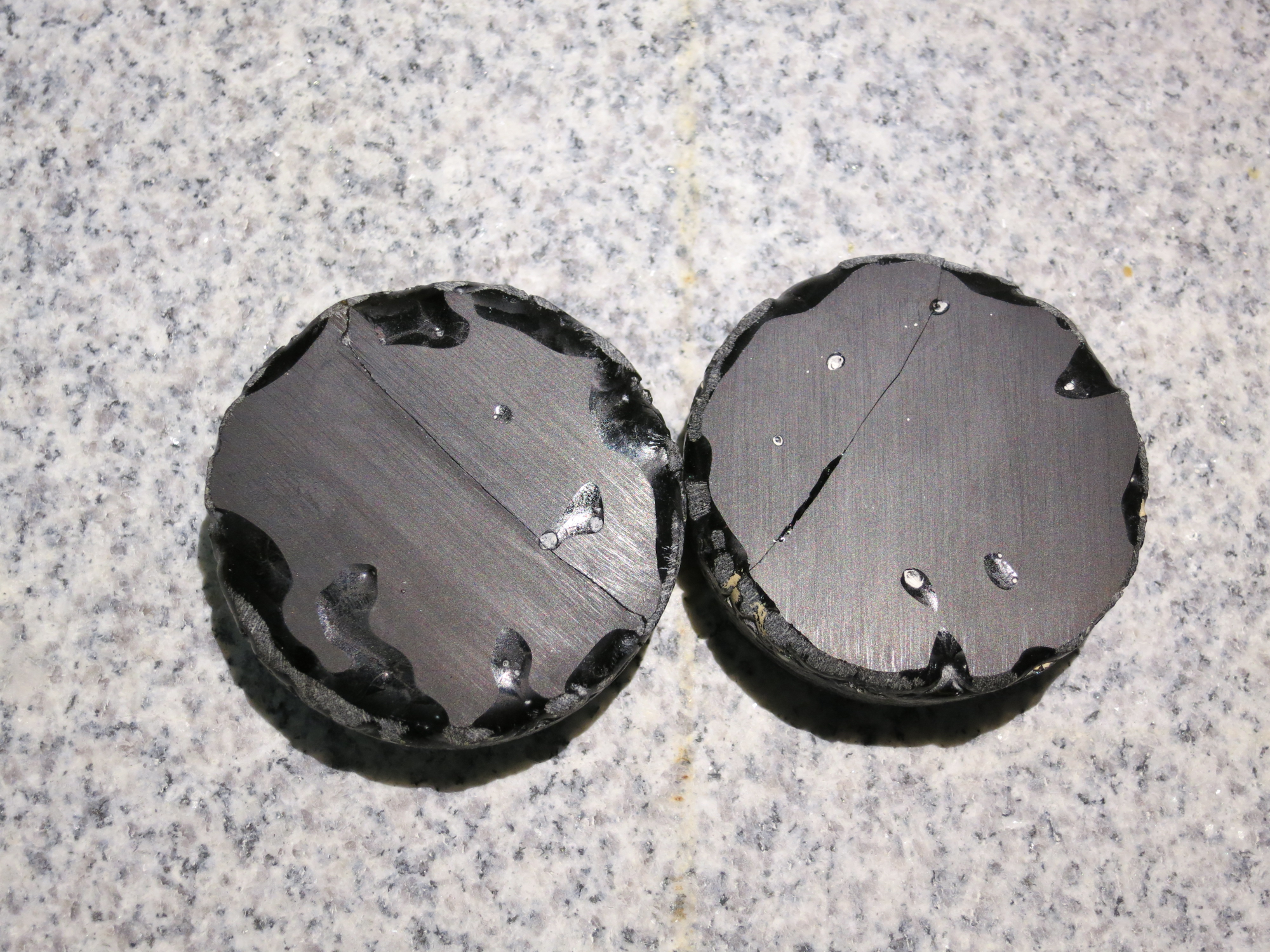

However during the rough grinding pass one of the slugs fell in half.

A gentle tap with a hammer split another in half too.

I believe there are two problems:

- There are veins of impurities running through the glass,

- These will create a weak point for a crack to start.

- My tempering profile could be improved,

- The current profile I'm using was created for tempering float glass. Container glass is slightly different, and so may require a different profile.

Video

What I want to accomplish next time

- Read this: https://www.instructables.com/id/Casting-Glass/,

- Read this: http://www.glasskulls.com/asending-sequence/,

- Adjust my temperature profile accordingly,

- Wash my glass in HCl to clean off impurities,

- Make better slugs.