Table of Contents

What I want to accomplish

- Build a machine to polish glass surfaces very smooth,

- Wring some smooth glass surfaces together,

- Characterise a wrung glass join.

THE MACHINE:

Wrong machine.

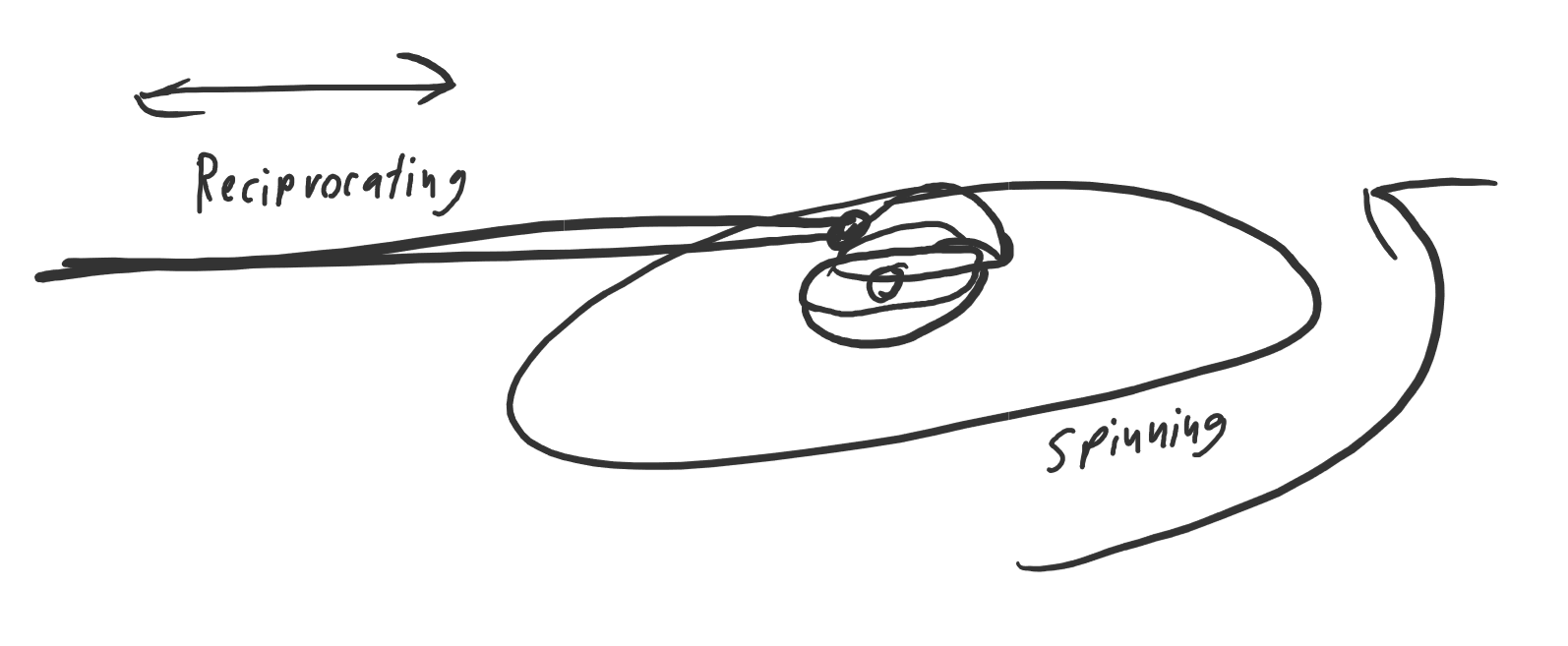

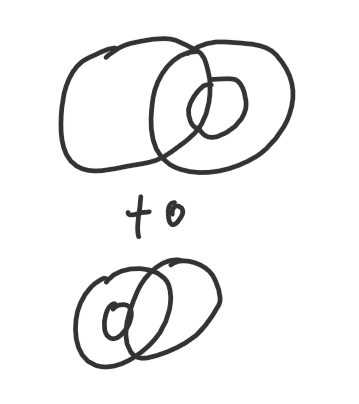

The idea is to ensure that each portion of each surface of both parts touches every other part:

Using the Three-plate Whitworth method I should be able to create very smooth and flat surfaces.

What I've done

I built a few rotating platforms. The first one was too weak, using a geared DC motor. I was using water and various grit compounds:

- Toothpaste,

- Titanium dioxide,

- Bicarbonate of Soda.

When the two test float glass pieces got wet and smooth-ish they would bind together very strongly, stalling the motor. I needed to build something with more power and some inertia to overcome the spiky friction.

My second pass was a bit better:

Using a scrounged office chair base, an old drill, some 3d-printed gears and a concrete round from bunnings. Shown here with some pottery on top, because it also worked as a pottery wheel. I used a variac to slow the drill down to a good speed. I ran into heat problems in the drill, and the office chair base was not as stable as I would've liked.

I ended up picking up a cheap pottery wheel off gumtree (classifieds website). I'll be using that in the future.