Table of Contents

Our First Outing

Soon after picking up the boat I enlisted Michelle's help in “stepping” (standing upright) the mast onto the boat on dry land for testing and practice. Neither of us fancied working out how to do this at a boat ramp with an audience. The mast has a pointy bit on the bottom that rests in a cupped divot on the middle lateral aluminium bar. The mast is held in place by three stainless steel wire “stays”. Two to the side and one to the front. These clamp the mast down to the boat. This feels as perilous as it sounds, but it seems to work.

It was wise of us to try this in the comfort of our own front yard - it took us a few goes to work out the order of operation. We ran into problems with weight distribution on the boat tipping the trailer up, and how best to lift the mast. Our first attempt lead to the mast being dropped onto a U-shaped mast rest on the trailer and the top end banging into the ground. Unfortunately my torso was above the shorter, lower arm of the balance lever and I spent three weeks enjoying some cracked ribs. I cannot recommend. We eventually worked out a sequence of steps to get the mast up and down with minimum calamity.

Now it was time to keep an eye on the weather forecast. We wanted a nice gentle 5-10 knots of wind and low chance of rain. Michelle and my sailing lessons were a few years ago now, and with two kids onboard a new-to-us boat we wanted to play it safe to build confidence before working up to some sportier sailing. Finally, on boxing day of 2023, we headed out for our first sail.

2023-12-26 Brisbane River

Brisbane has a river running through it, dotted with boat ramps. River sailing is generally safer because there's more boat traffic to help out if you get into a pickle, and the shore is always swimmably close if worst comes to worst. There are downsides though: Messy wind due to obstructions and lots of anchored boats to dodge. Our closest boat ramp is a ten minute drive from home, in the Colmslie Recreation Reserve. We'd been geocaching there in the past, and we'd been out more recently to scope out the lay of the land.

Our modest goal for the day was to get out on the water and make it about 1km downriver to the Colmslie Beach Reserve and back. We turned up bright and early, ribs aching, and stood the mast up in the parking lot. The boat and trailer combined are light enough for two adults to comfortably maneuver, even on a slippery ramp, so we unhooked from the car and wheeled it down to the water. We let it off the trailer and tied off to a cleat at the end of the dock. I got the sail situation sorted while Michelle hauled the trailer back to the car.

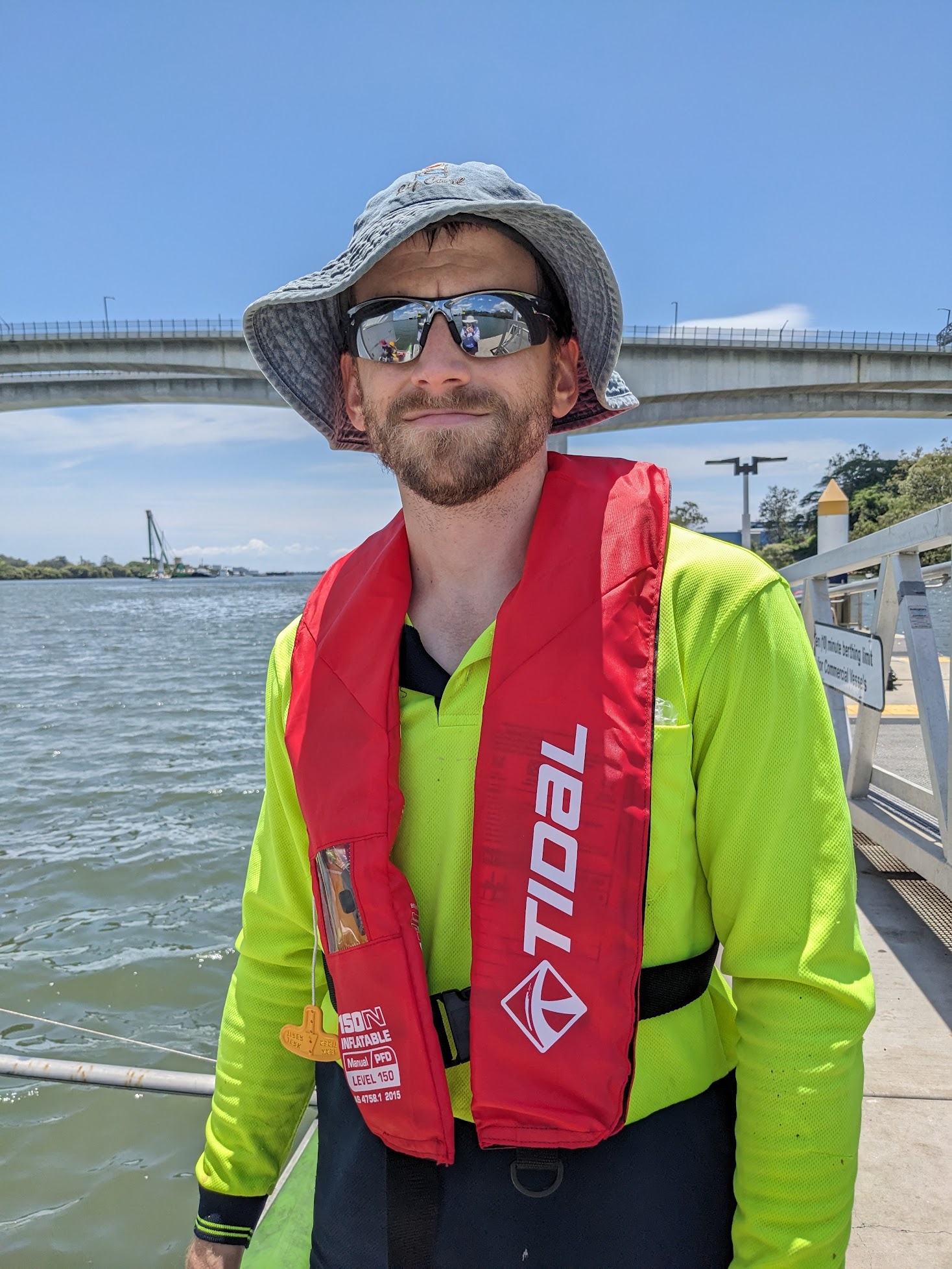

This was the first time I'd actually fully rigged this boat. The family patiently waited while I remembered the difference between a halyard and a cunningham and got the sails up in one fashion or another. Meanwhile, a kind gent living on a boat in the river gave us his phone number in case we needed a tow back to the dock. I am sure this was mostly due to the innate mutual respect shared between all humankind, but also partially due to me repeatedly failing to fasten the jib halyard into a clearly ineffectual cleat. I eventually tied it off to a random loop on the mast and hoped for the best. Then we all got our life jackets on, clambered aboard and cast off into the wide-ish brown wonder of the industrial end of the Brisbane river. All told we were underway in about 40 minutes. Not great, not terrible.

It was fucking fantastic. The wind was perfect, there was little traffic, and the kids were excitedly gabbling about everything that hove into view. Whenever a motorboat went past we'd steer into the wake and bounce up and down, laughing at getting splashed. We tacked back and forth up towards the Gateway Sir Leo Hielscher Bridges and tied up to the jetty next to Brewdog Brisbane for a breather and a stretch. My ribs were emphatically informing me of an upcoming bill, payable in ibuprofen. We considered going into the pub for lunch, but we didn't feel our attire was restaurant-compatible.

We made a straight run downwind back to the boat ramp. As we passed the incomprehensibly massive car carrier in the photo above the crew shouted out a merry Christmas from their deck 30m above the waterline. We caught the jetty and disembarked without incident. I dropped the sails (into the water, erk) and we got the boat back onto the trailer easily. In the car park I took out the bungs and we tilted the boat up. About five litres of water poured out of the left port pontoon. This was only mildly alarming. It wasn't enough to meaningfully affect the boat during short sails, but it would need to be addressed if we were to go on longer trips.

In summary: Fantastic success. We did not hit anything or sink much, we learned about our boat and how to make it go, and meet some nice people while out and about. The kids loved it and Michelle was enthusiastic about another outing soon.

Repairs

When we got home and cleaned up I thought I'd try to find the leak in the left pontoon. I wrapped a thick bundle of gaffer tape around the end of a compressed air gun and wedged it in the bunghole with a cable tie providing a gentle trickle of compressed air. I then sprayed soapy water all over the boat looking for bubbles from escaping air. The bottom-most bit (keel) on caper cats has an aluminium strip riveted along the length to protect it during beaching. I'd previously repaired the leading edge of the one that had come slightly loose on the other side, so I figured there might be some water getting in through a small hole there. I was wrong. Everything seemed airtight except for the top front bit where the top and bottom fibreglass halves were held together by an aluminium casting.

I was confused; only a little bit of water splashed over the front during our outing, when driving through wake from other boats. Finding no other leaks I took off the casting, prised the fibreglass apart a little bit and blorked in some construction adhesive and clamped it overnight. I then followed up with a liberal quantity of “roof and gutter” silicone I had leftover from fixing a roof and/or gutter. I reinstalled the casting and congratulated myself for completing my first moderately serious boat repair. Ominous undertones intended.

Financial stuff

The “Bring Out Another Thousand” acronym is a well worn warning about the hidden costs of owning a boat. There's always something to improve or fix, so it's easy to spend more than you expect or intend. Our caper cat was in good nick when we bought it, but there were a few things that needed to be done before we could take her out.

I've categorised our boat-related spending into “Fixed to boat” and “Not”. The former (nominally) contribute to the value of the boat and would go away if we sold it. The latter is stuff we'd keep after selling the boat and could re-use if we bought another boat. This categorisation has no real effect but grants me a feeling of control over the process.

New Jib

At the top of the list was the jib. That's the front sail. The original jib was a total wreck. Technically we could sail without a jib but we'd be losing a lot of sail area and we'd have to waste a lot of energy steering with the rudder. The jib and mainsail act to balance each-other to keep the boat going in a straight line. Without the jib we'd need to correct our direction with the rudder constantly, spending our precious wind power to generate turbulent water in our wake. No bueno.

Caper Cats aren't made anymore, so we couldn't buy a replacement off the shelf. Having sails custom-made is expensive, like “more than we paid for the boat” expensive, so I measured some dimensions and found a roughly suitable second hand sail on Sail Exchange. This website lets you search by the various edge lengths, price and quality to find something suitable. The replacement was AUD$200 delivered and arrived in a few days. It was rated 5/10 on the quality scale, but it was in far better condition than any sail I've ever seen.

Our sailing instructor told us that hardcore racing sailors sell their old sails after one or two seasons of sailing. A clapped-out racing sail still makes for an awesome casual pootling sail. I'm not sure if that's where ours came from, but I'm happy with it.

Rigging

Tiresome pedants love to say that sailboats have no ropes, but it's reasonable to ignore them and enjoy a better life as a result. There are ropes everywhere and they all have weird names that predate modern English. Some of these ropes are made of steel. These are collectively called “fixed rigging” and generally don't move much when sailing. These are in contrast to the “running rigging”, which are the ropes you pull on to make the boat go places or stop going places.

I had to install a new luff line along the leading edge of the new jib, and one of the mast shrouds had worn down to a few strands on one end. The shrouds are steel lines that run down the outside of the mast to add stiffness. If a shroud snapped the mast would wonk over sideways like a banana. This is bad for sailing. For this work I would need to pick up a spool of stainless wire, some thimbles, some swages, some shackles, carabiners and a swaging tool. Farewell to another AUD$200-ish.

“Swaging” is a fancy word for “squashing a thick metal tube around a wire”. It's a good way of making a strong join in braided wire. A thimble is an insert that goes inside a loop of wire to enforce a minimum bend radius. The old shroud was close to failure because the thimble was absent; the cable was fatigued by the sharp bend.

Image source This is not a photo from our boat.

Image source This is not a photo from our boat.

Safety Gear

Life Jackets

We got regular life jackets for the kids, and fancy pull-a-rope-to-inflate life jackets for the adults. They aren't too expensive when you consider what they do. We were looking at them at the shops and Sam (5) asked “This one daddy?” and yanked the inflation cord of a hanging life jacket. Fortunately it just fell off the hook rather than inflating. Kids are great. We got three life jackets for AUD$170 due to a scanning error we didn't notice until we got home. Bonus!

Radio

A marine VHF radio is an important piece of safety gear. If you're heading out into open water you can use it to call in to the Volunteer Marine Rescue folk and let them know the number of people onboard, where you're going and when you expect to be back. This means they can send someone to fish you out if you go missing. It's also handy for calling for help if you need it. I asked a radio nerd mate of mine (thanks VK4BRY!) for some advice. He recommended an ICom radio with at least 5W transmit power. I searched around and found a good price for an ICOM IC-M25 on ebay.

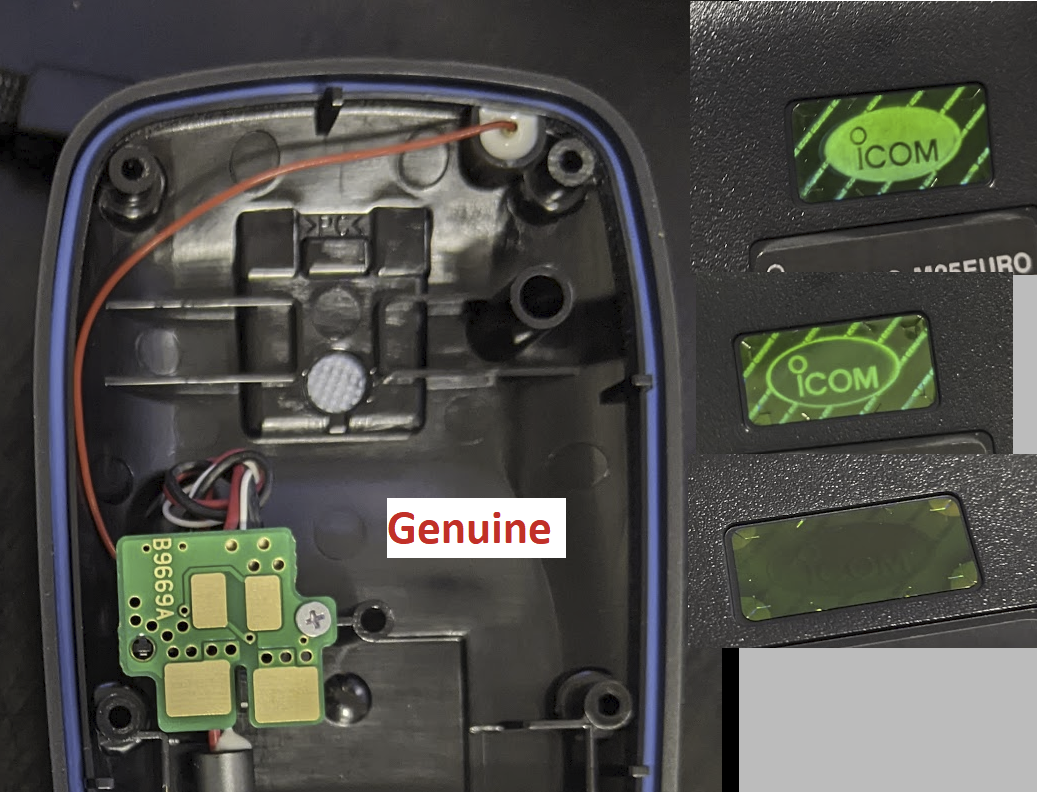

I had a play with the radio when it arrived. It worked fine, but the holographic sticker on the back didn't match the description on ICom's website. My suspicion piqued, I took the back housing off and found the immersion sensor pad wasn't connected to the rest of the radio. Hm. Hmmmmmm.

I requested a refund on ebay and posted it off. At time of writing I haven't received a refund. I ordered another radio from a more reputable storefront for a AUD$50 premium. I had some lingering doubts about my counterfeit assessment of the first one, but these were dispelled by the sticker on the new radio that exactly matched the description. And it had more wires inside, which is usually a good thing.

Charts

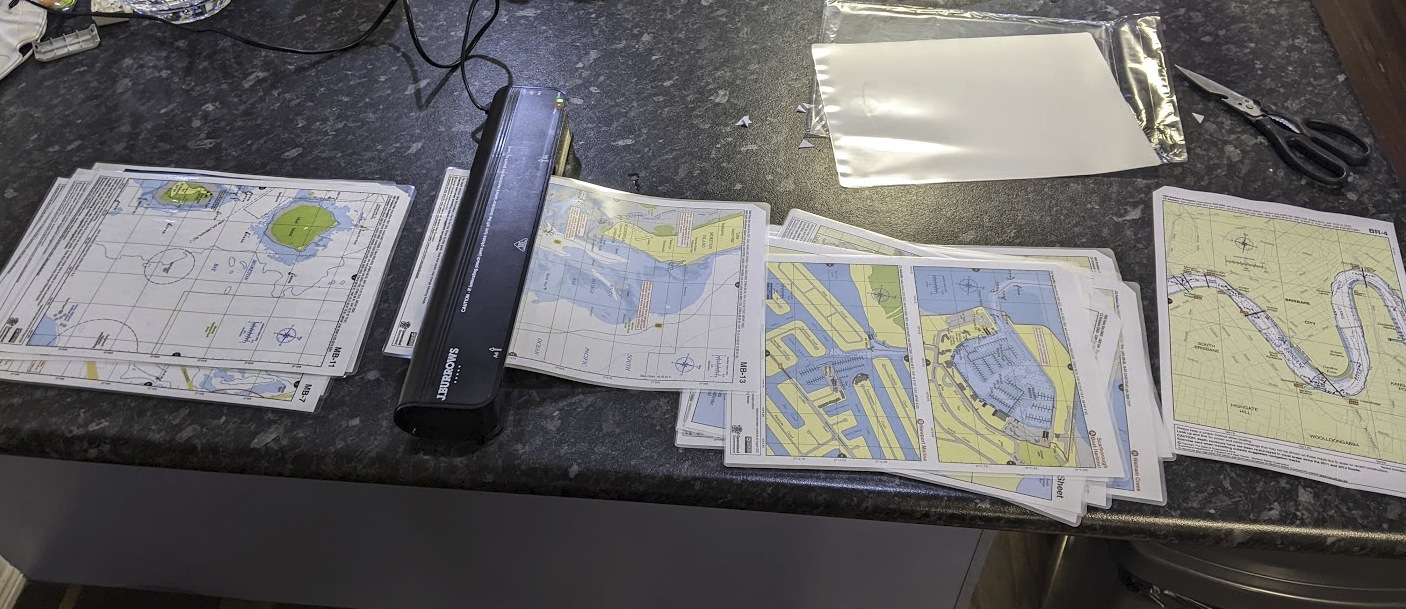

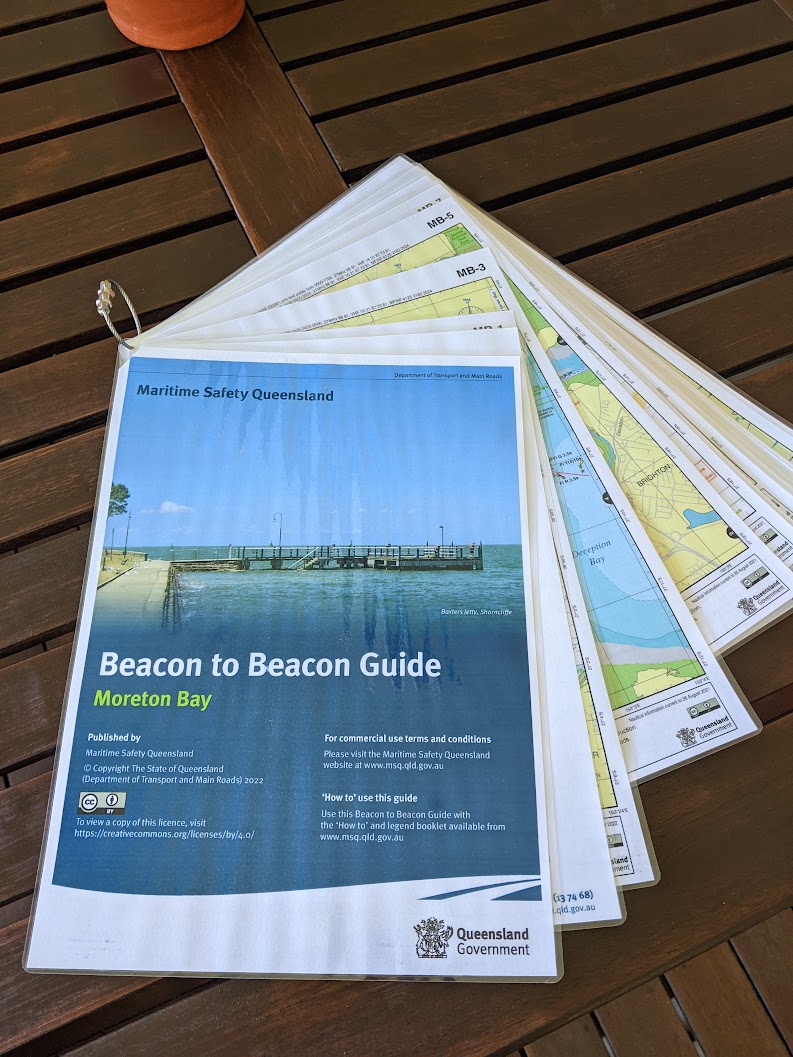

Charts (or maps) are important for telling you where things are. You, navigation markers, no-go zones, areas with special rules, boat ramps, water, land, things like that. They also usually show the depth of the water at low tide so you can avoid running aground. This is less of a concern for us because our boat is designed to run aground for fun, but it's a bigger deal for keelboats (boats that poke deep into the water). There are good charting apps for mobile phones, but as a software engineer I have an innate distrust of most software. I decided to go with paper charts. Maritime Safety Queensland publish an excellent set of charts, licensed under creative commons, that are designed to be printed A4. I printed them in double-sided colour at Officeworks and bought a pack of lamination pouches. Bon voyage, AUD$46.30.

I ended up cutting off the fetching swaged stainless wire loop and using a keyring instead. Works much better. I could've bought a pre-made book of charts, but it was slightly more expensive than making it myself, and included a bunch of charts I'd never need.

Everything Else

There were many other odds and sods for various things. The running total is up to AUD$2815.50. Oootch. I hope we use this boat lots.

| Date | Item | Source | Price | Postage | Fixed to boat | Note |

|---|---|---|---|---|---|---|

| 2023-12-16 | Boat | A guy | 1600 | 0 | Yes! | |

| 2023-12-17 | Bunnings | Bunnings | 80 | 0 | Tape, glue, fabric, shackles | |

| 2023-12-18 | Jib | SailExchange | 189 | 15 | Yes | Old jib shagged |

| 2023-12-19 | Radio Icom IC-M25 | Ebay | 180 | 0 | Safety | |

| 2023-12-20 | Tarp and straps | BCF | 156.97 | 0 | Cover boat | |

| 2023-12-20 | Life jackets | BCF | 169.97 | 0 | Charged us for two kid and one adult. | |

| 2023-12-20 | Trailer cable adapter | BCF | 36.99 | 0 | Rectangle to circle | |

| 2023-12-21 | Swages, swager, thimbles | Bunnings | 176.1 | 0 | Shroud repair | |

| 2023-12-21 | Sail repair tape | Ebay | 29.9 | 0 | Jib patch | |

| 2023-12-22 | Rope, shackles, thimbles | Bunnings | 38.8 | 0 | ||

| 2023-12-29 | Glue | Bunnings | 7.99 | 0 | ||

| 2023-12-27 | Charts | Officeworks | 46.3 | Printing and laminating | ||

| 2023-12-29 | Radio Icom IC-M25 | Whitworths | 229 | 32.53 | Other radio counterfeit | |

| 2023-12-29 | Jam cleat | Whitworths | 6.95 | 0 | Yes | |

| 2023-12-29 | Radio refund | Ebay | -180 | Not refunded yet. |

Sailing!

I have fond memories of boating as a kid. We owned a centre-console aluminium dinghy, and we went out fishing with friends of the family regularly. We went on trips on bigger boats out to Fitzroy Lagoon, or other spots on the Great Barrier Reef. We rode the car ferry over to K'gari (neé Fraser) Island about once a year for camping. The deep diesely thrum and stench of that ferry is forever buried in my hindbrain.

Years later Michelle (my wife) and I decided to do some sailing lessons at the Royal Queensland Yacht Squadron. We started their helming, crewing and skippering courses. I just finished the course just in time for 'rona to ramp up. We were sailing the Elliott 6 keelboat during the lessons. Our instructor, Austin, was utterly unflappable in every situation, even ones with lots of flapping. We developed a habit of keeping an eye on him because he would regularly throw one of the fenders overboard to make us practice yet another “man overboard” manoeuvrer.

We loved being out on the water with no engine sounds or smells. Zooming around with only the wind. Very peaceful and only a little bit of panic during a hairy tack or exciting gust. In late 2023 we were on a holiday in Caloundra and rented a Hobie 14 (maybe?) for a sail up and down the Pumicestone Passage. We got the boys on-board and had a brilliant time and only got stuck on sandbars three or four times. That night I did a survey of various buy/sell services and discovered that little catamarans like the Hobie were A) Trailerable, and B) Relatively inexpensive, roughly 20 times what we paid to rent the boat for an hour. I mentioned this to Michelle and she was surprisingly enthusiastic on the idea of buying one.

After a moderate amount of research and guidance from more experienced sailor friends we ended up driving to the Gold Cost to check out a 14' Caper Cat. This boat was designed and manufactured by the folk at Calypso in Brisbane, where we live. They're on the same scale as the Hobie we sailed, but with lots of storage space inside the pontoons, designed for stowing camping gear. The idea of loading up and scooting across to an island in Moreton Bay or a quiet spot on Wivenhoe was very tempting.

I had a list of things to check before deciding to buy:

- Soft spots on top

- Soft spots on sides

- Joins between aluminium and fibreglass

- Cracking around fibreglass joins

- Mast step cracking

- Mast straight

- Rudders OK

- Cracks around rudder mounts

- Trampoline wear

- Sail boltrope

- Sail eyelets

- Blocks

Everything looked pretty good on this specimen, except the hull was slightly soft *everywhere*. This confused me, but the price was right so I haggled down $50 to account for the tattered jib and drove home in one of the worst storms south-east Queensland has seen in years. I do not wish to repeat the experience of doing 80 km/h in a 110 km/h zone with 20m visibility towing a trailer of unknown integrity while lightning flashed around us. Scary shit.

After some investigation I found the hull softness wasn't a problem on the Caper Cat. It's a warning sign on boats filled with expanding polyurethane foam as it indicates the foam has started to break down with age. The Caper Cat gets its positive buoyancy from dozens of sealed plastic bottles stuffed into the insides of the pontoons.

We're now boat owners, it seems.