Table of Contents

What I want to accomplish

- Design the 3d printed parts,

- Print them,

- Assemble everything.

What I've done

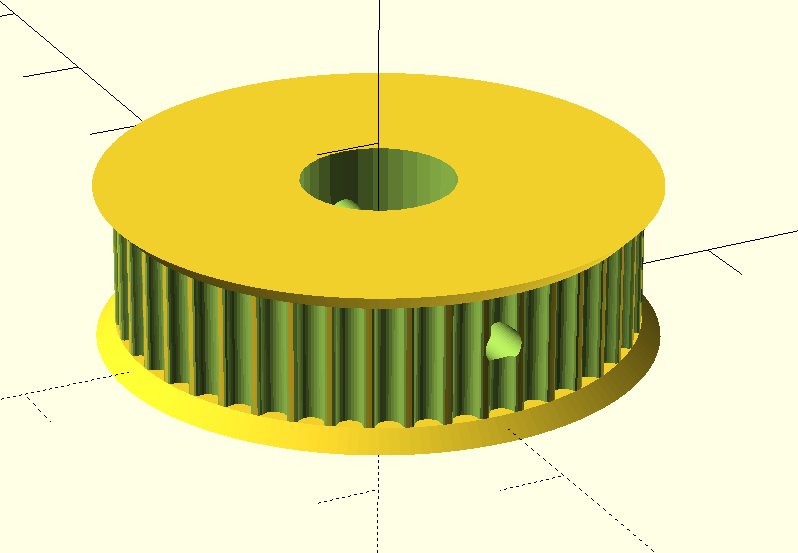

I broke out my favourite CAD tool: OpenSCAD and wrote a bunch of code. I found an openscad library on Thingiverse that can generate GT2 pulleys. My belts aren't quite GT2, but they're close enough.

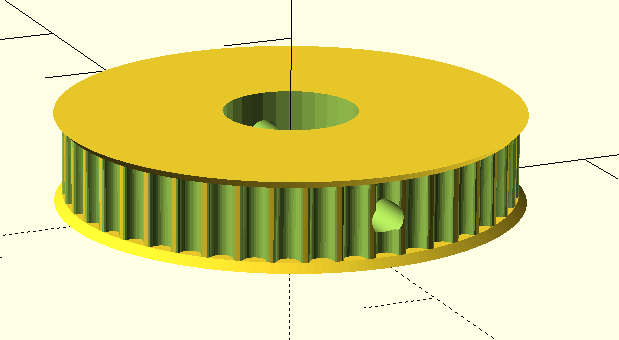

I decided on 8mm shafts because I have a large number of 608 bearings, and they have an 8mm ID. I sized the pulleys to get the required spacing between the stepper shafts and the first axis shaft, around 27mm OD, which works out to a tooth count of 44. The stepper pulleys have 20 teeth. I made the holes for the stepper motor mounts slotted to allow for tensioning the belts. I did the same for arm 1.

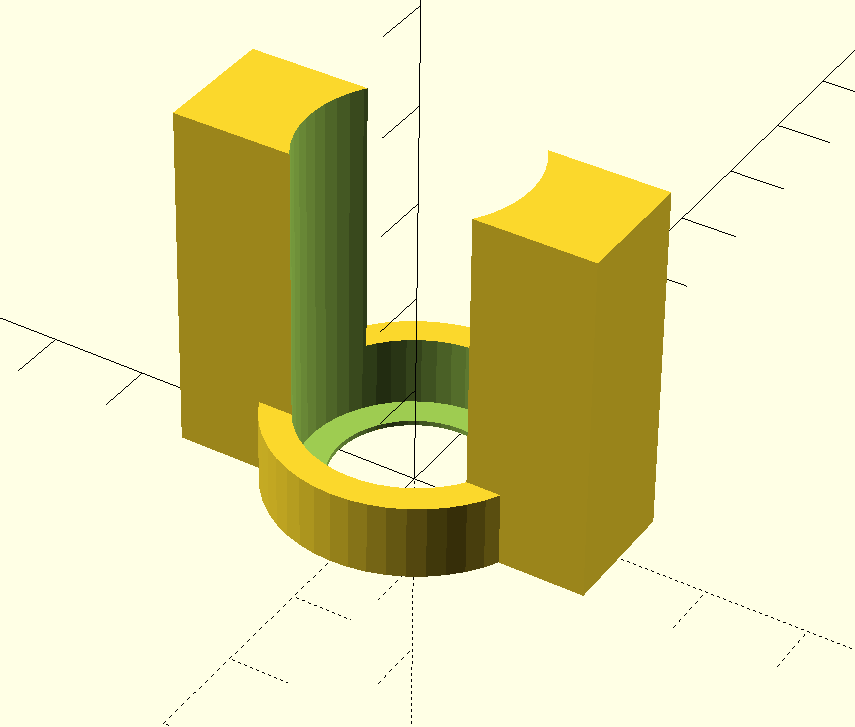

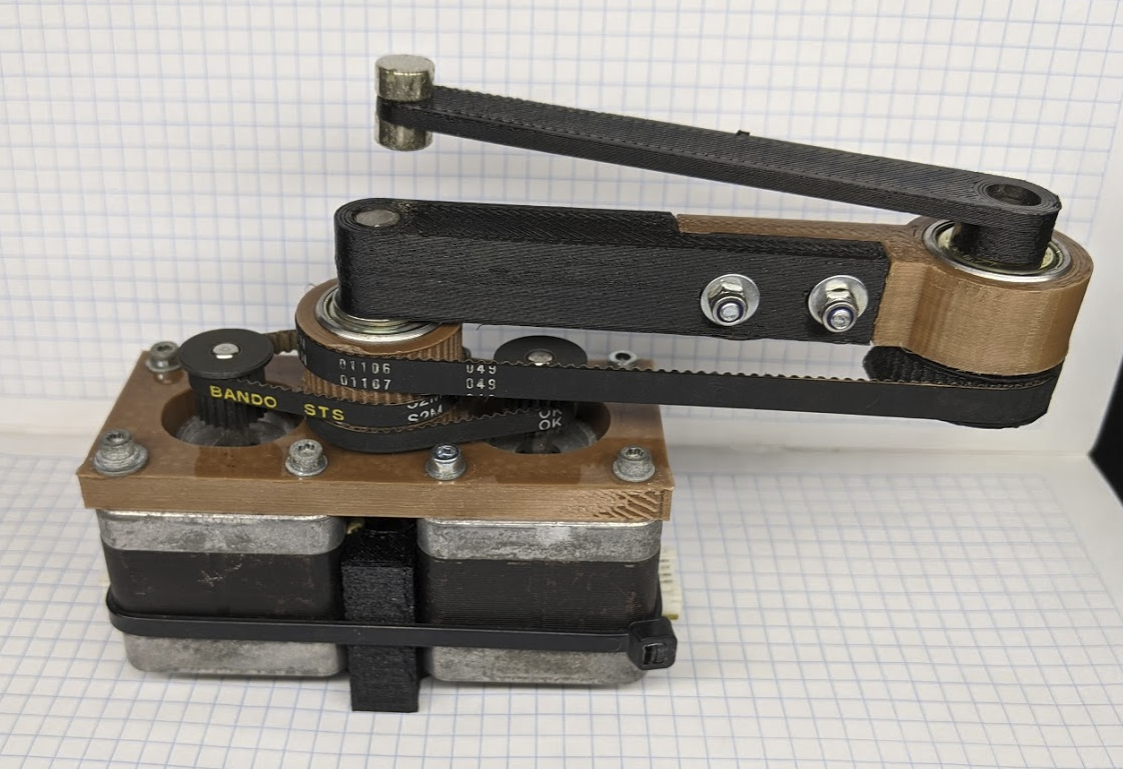

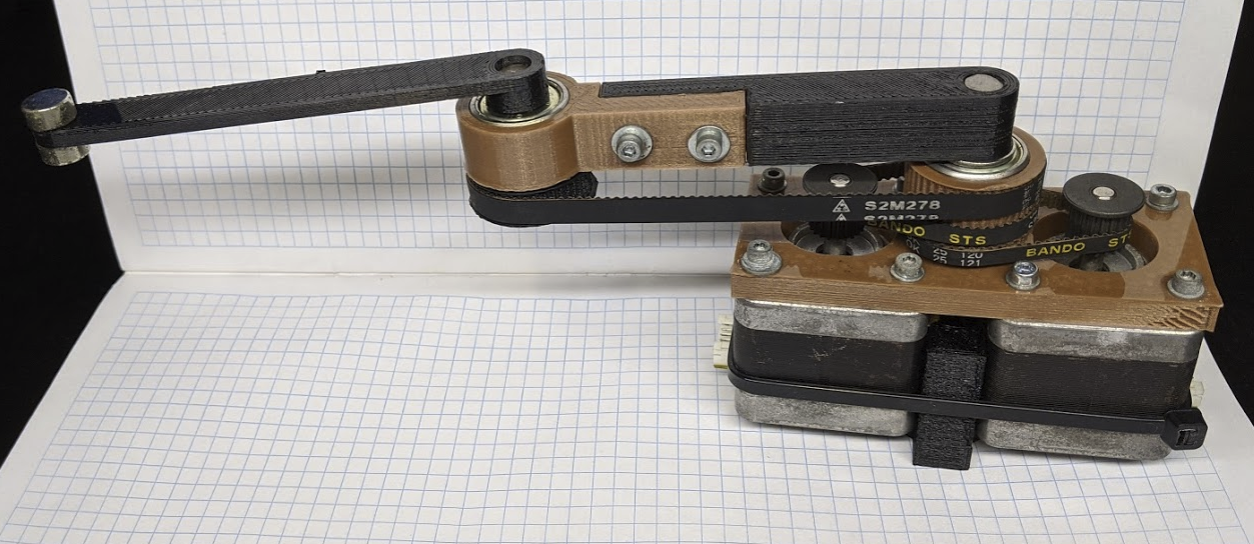

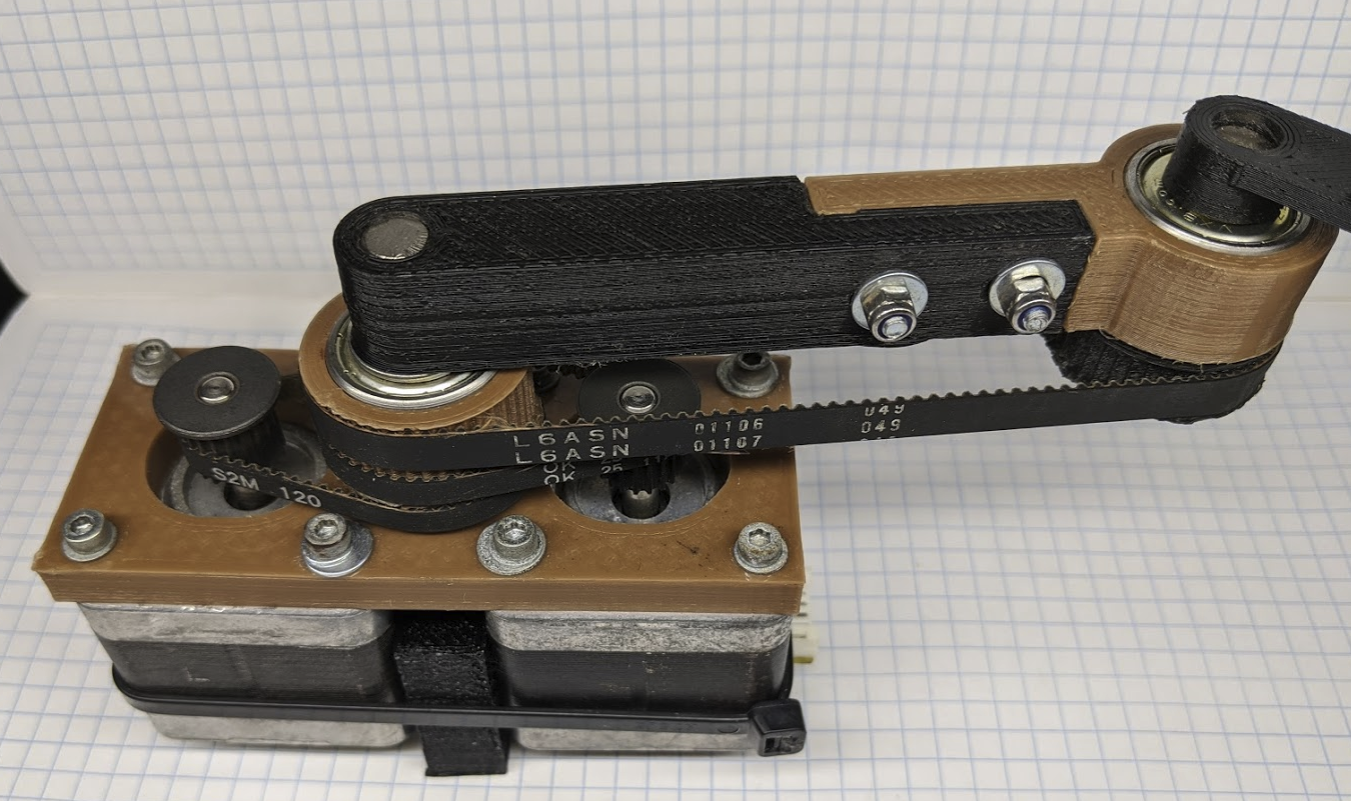

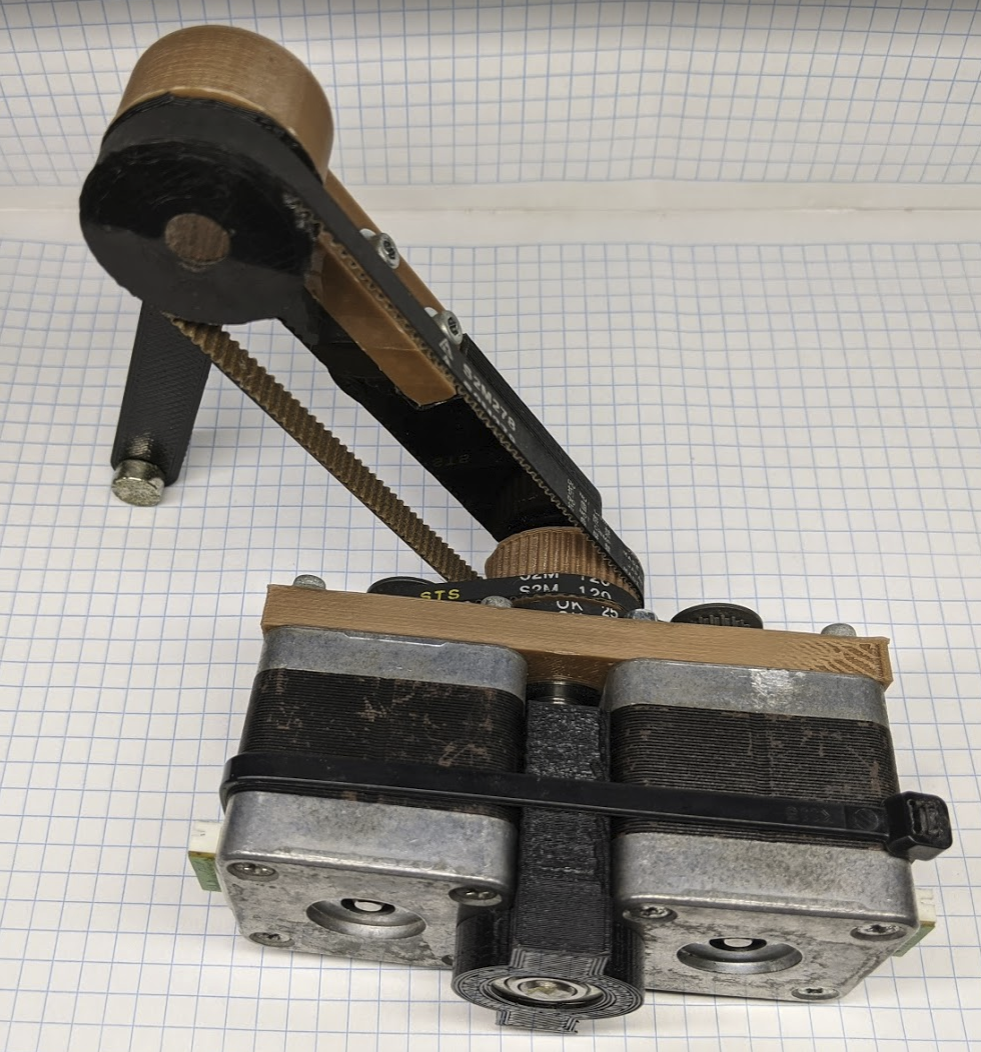

It was a bit of a challenge to design the bottom bearing holder. I can't use the bolts holding the stepper together to mount the bottom plate, since removing bolts from a stepper is generally a bad idea. It's important that the bearing be in the correct place as that determines the belt tension. I ended up making a piece that fits between my steppers with my belt tension. Not ideal, but perfect is the enemy of done.

This fits between the steppers to hold the bottom bearing in place. The steppers are clamped together by a cable tie.

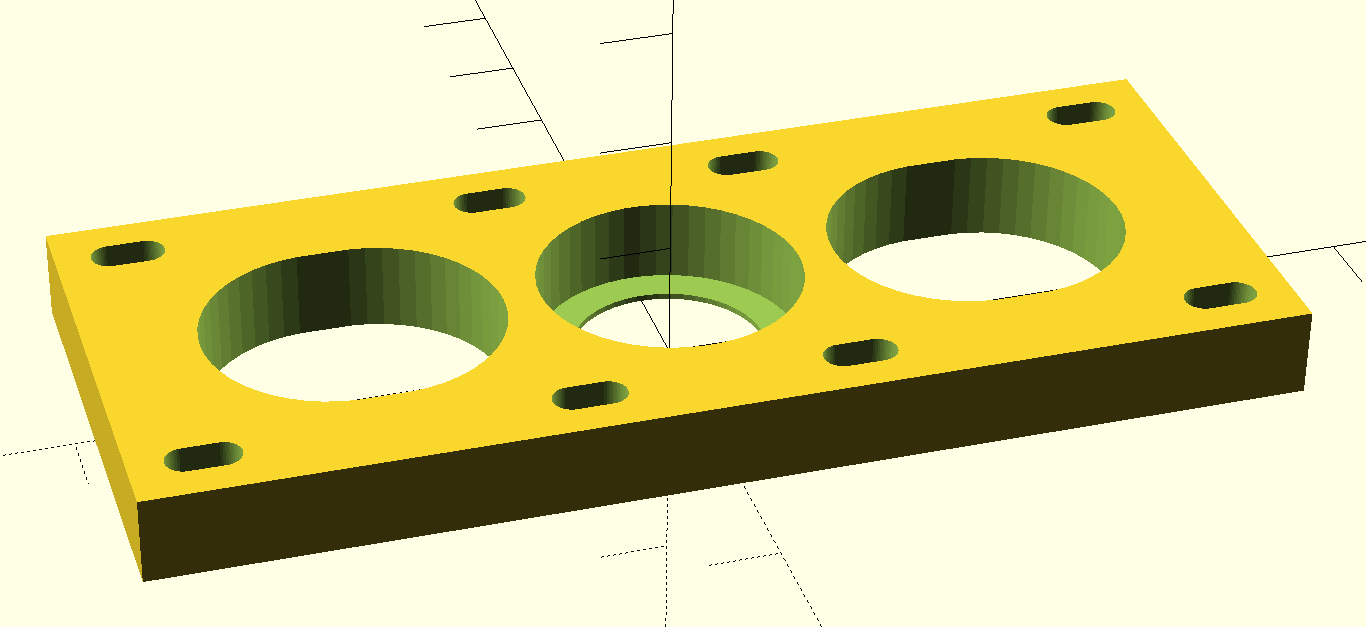

The steppers mount to this, retaining a bearing in the centre.

This is pinned to shaft 1 and driven by a stepper via a belt.

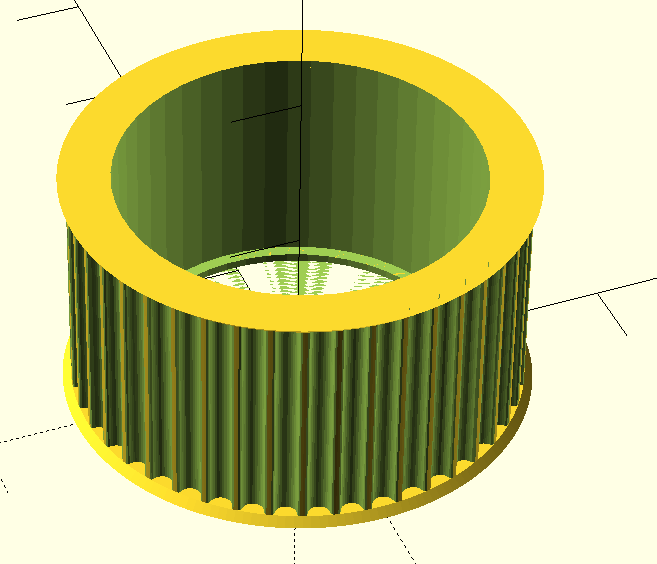

This holds two bearings and sits next on the shaft above the shaft 1 drive pulley. It is driven by the other stepper and drives the shaft 2 driven pulley.

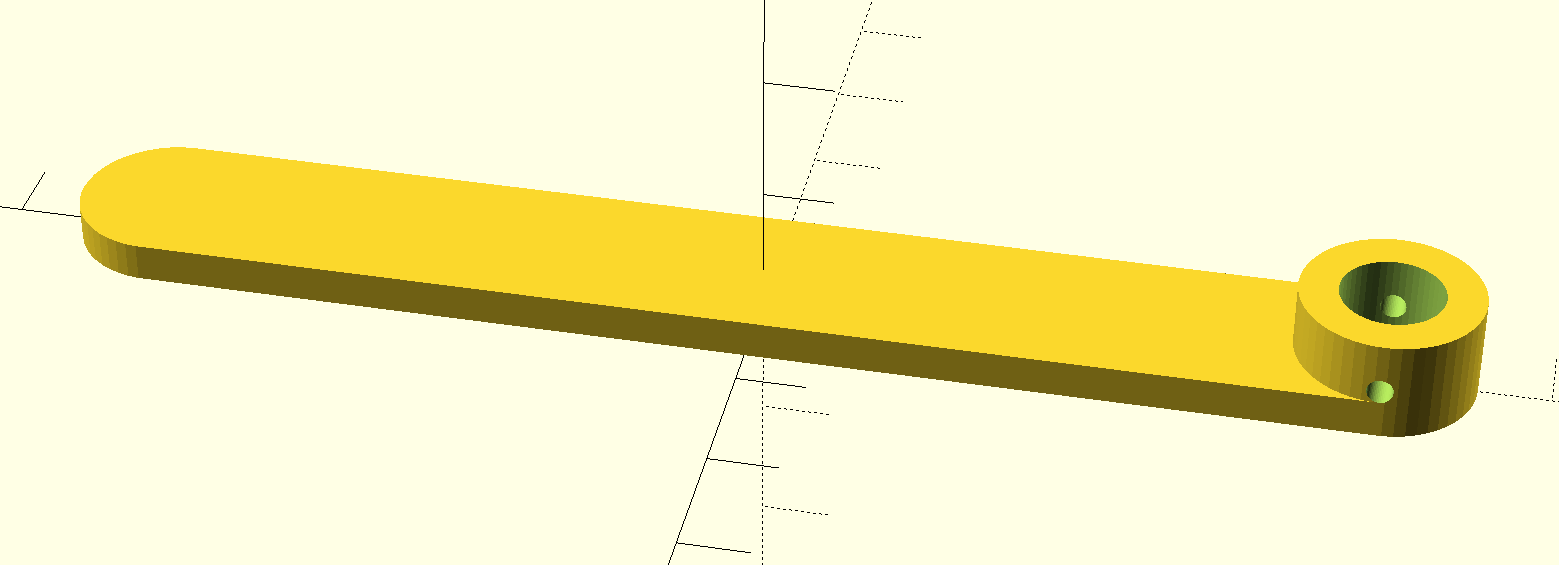

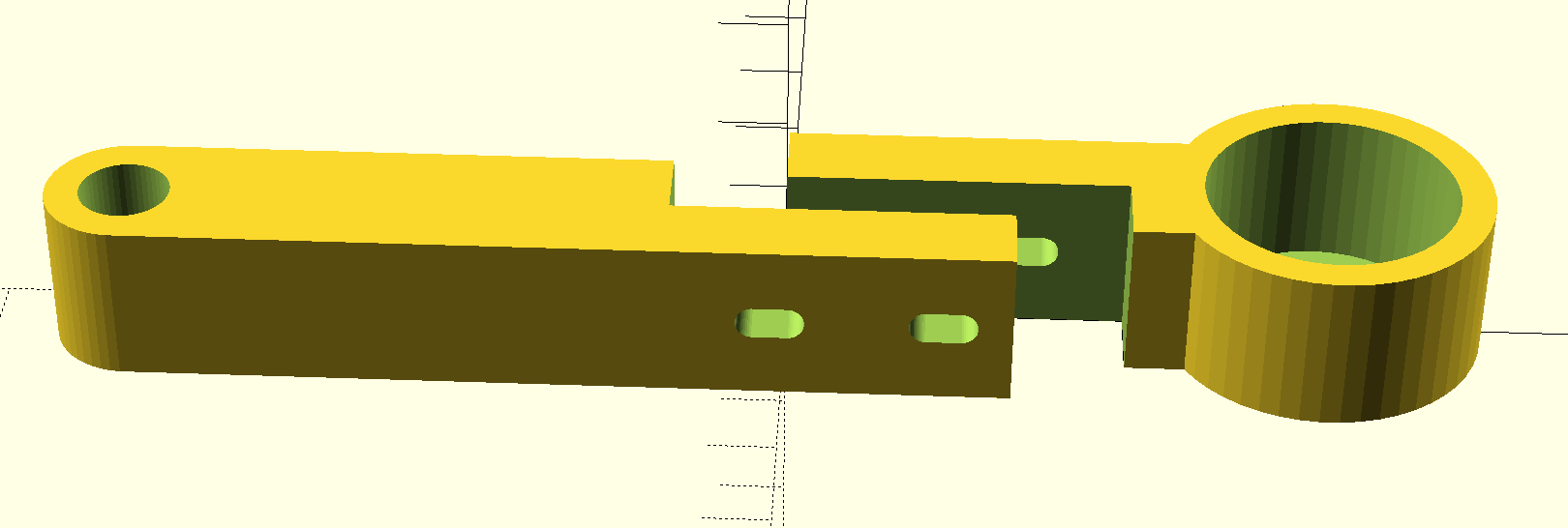

arm1\_split\_base and arm1\_split\_end

arm1\_split\_base and arm1\_split\_end

The smaller hole is pinned to shaft 1. Two bearings are retained in the big end to hold shaft 2.

Pinned to shaft 2 underneath arm 1. Slightly taller than the shaft 1 drive pulley to allow for a wider belt.

Pinned to shaft 2 above arm 1.

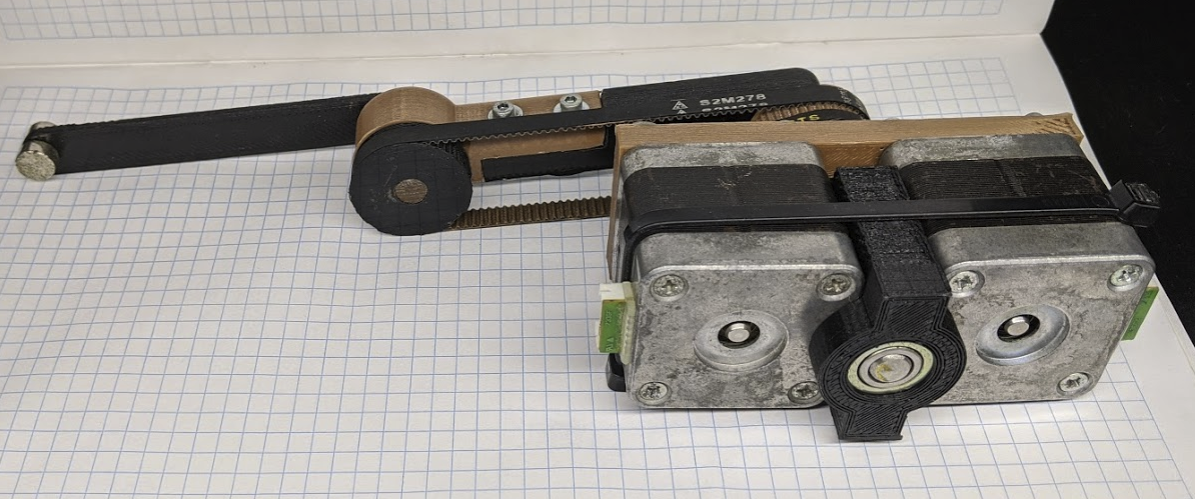

Assembled

Bill of materials

If I were ordering these parts for a build I would order at least 20% extra, especially the washers. They're cheap

| Item | Type | Count | Note |

|---|---|---|---|

| Printed parts | Various | 8 | |

| Stepper motor | NEMA-17 | 2 | |

| Stepper pulley | GT2-20, 12.35mm high | 2 | My steppers had pulleys from the factory. |

| Belt | S2M belt 120mm | 2 | S2M ≈ GT2. |

| Belt | S2M belt 278mm | 1 | |

| Shaft 1 | 8mm x 90mm | 1 | Mild steel is easier to cross-drill than stainless. |

| Shaft 2 | 8mm x 33mm | 1 | |

| Bearing | 608 | 6 | |

| Washers | 8mm ID, 15.7mm OD | 5 | OD not critical, but it must not rub on outer race of bearings. |

| Washers | 3mm ID, 6.8mm OD | 12 | |

| Bolts | M3x12mm | 8 | I used all 20mm and cut them to length. |

| Bolts | M3x20mm | 2 | |

| Nylock nuts | M3 | 2 | Nylock not critical. |

| Pins | 2mm diameter | 5 | Roll pins would be best, I used nails. +1 extra for pinning shaft 1 into the bearings. |

| Magnets | 10mm diameter, 5mm high neodymium | 2 | Dimensions not critical. |

| Cable ties | 200mm x 4.6mm Nylon | 2 | Dimensions not critical. |

What I want to accomplish next time

- Write the software