Table of Contents

What I want to accomplish

- Work out how Sandsara works,

- Scrounge the bits I need.

What I've done

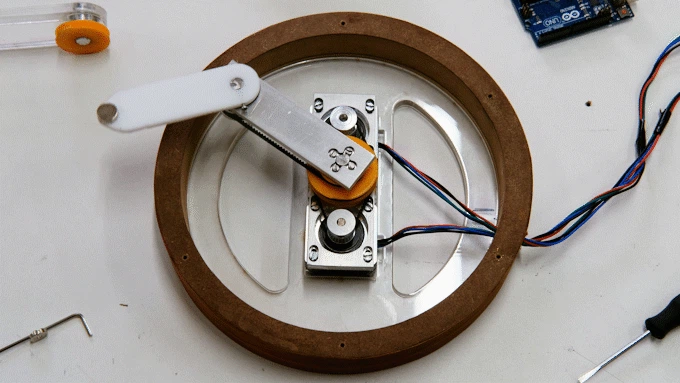

The Sandsara Kickstarter page has a nice little gif showing the internal workings of the mechanism. Here's a still from that gif:

Here we can see the two arms, driven by two stepper motors. The bottom stepper drives the first arm, the top stepper drives the second arm. The first arm seems to be fixed to the first axis shaft, and the shaft is driven by a belt-driven pulley connected to the bottom stepper. The second arm is likewise fixed to its shaft, which is driven by a belt from an idler pulley freewheeling on the first axis shaft.

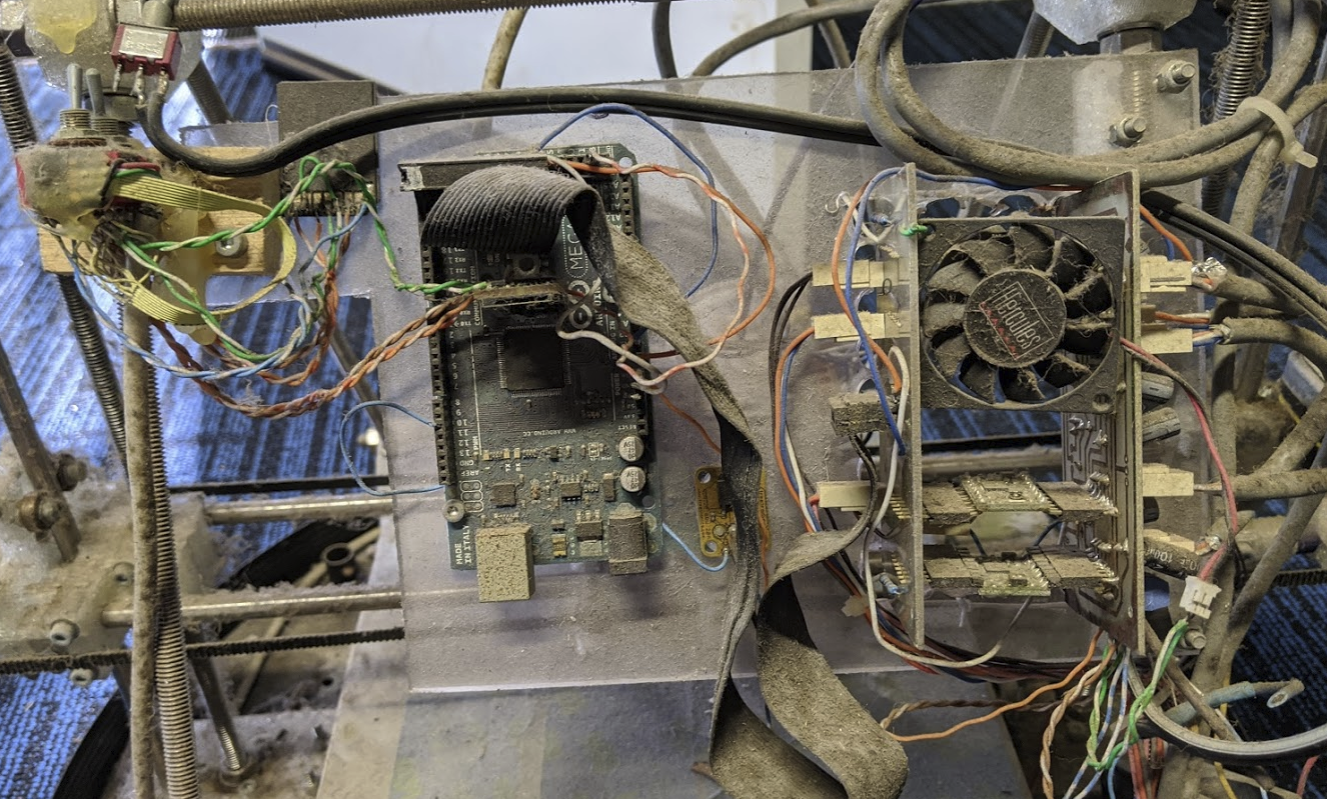

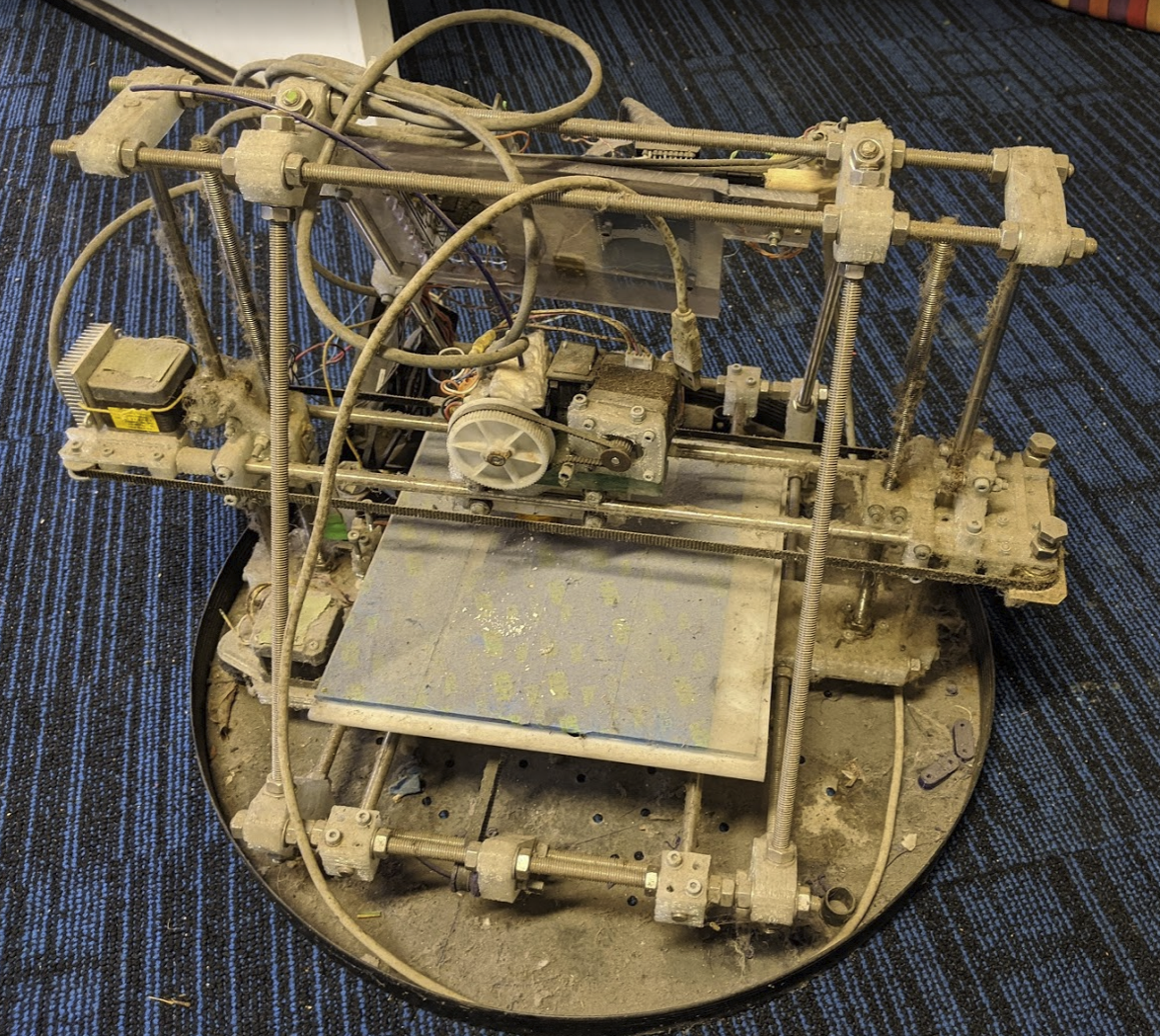

I have an old reprap mendel I've been meaning to either sell or dissect for parts. It's the grandchild of Adrian Bowyer's reprap, via HSBNE's printer. It printed my current printer a few years ago and has since been languishing on a shelf. It has four NEMA17 stepper drivers and lots of GT2 belt. It also has four Pololu stepper drivers. I also have a box of leftover reprappy bits.

Old faithful. One of the first reprap 3d printers in Australia.

Old faithful. One of the first reprap 3d printers in Australia.

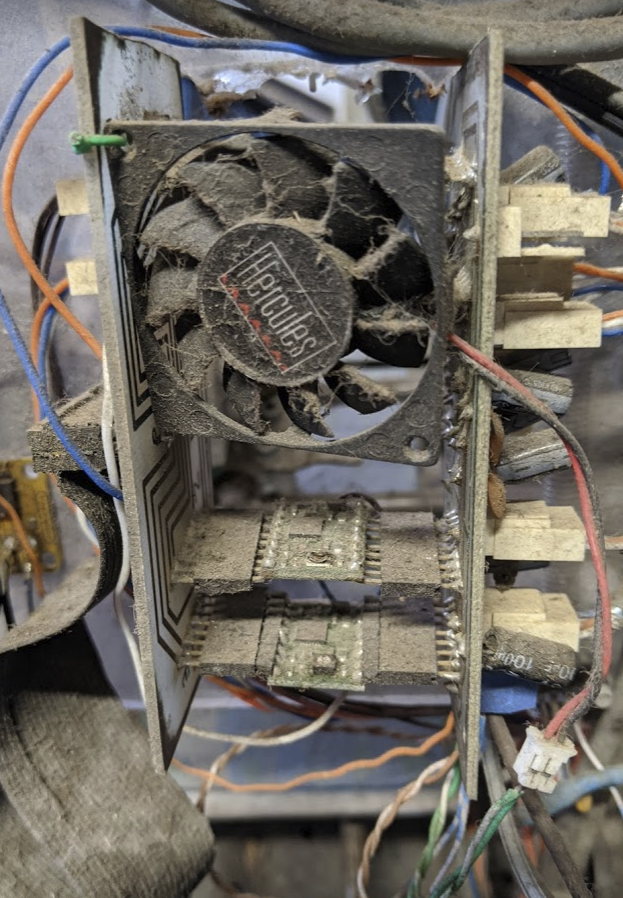

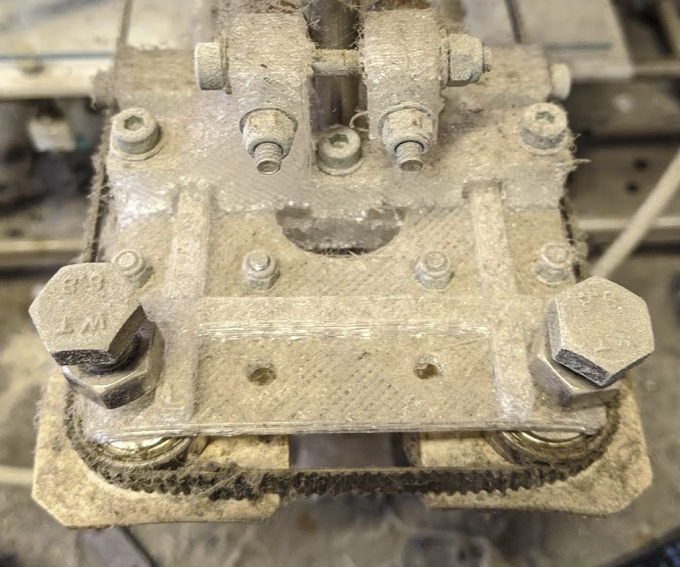

Non-standard Z axis bodge to change belt pitch.

Non-standard Z axis bodge to change belt pitch.

Very dirty. This is the old hand-made “sandwich” style of reprap electronics.

In the early days of home 3d printing the standards of quality were somewhat lower.

In the early days of home 3d printing the standards of quality were somewhat lower.

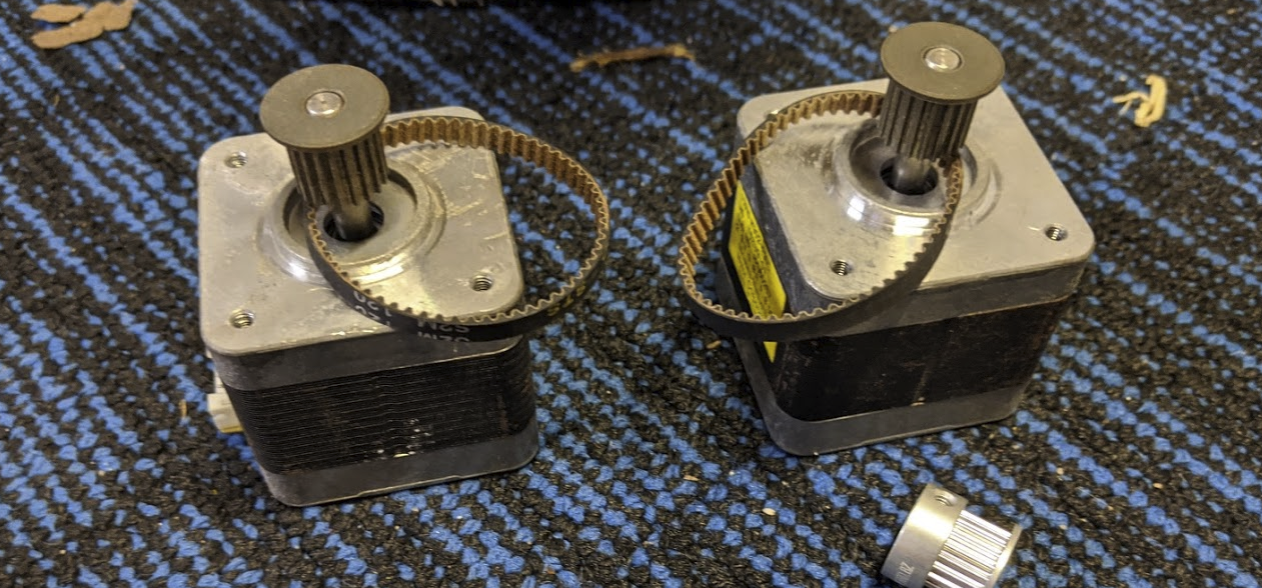

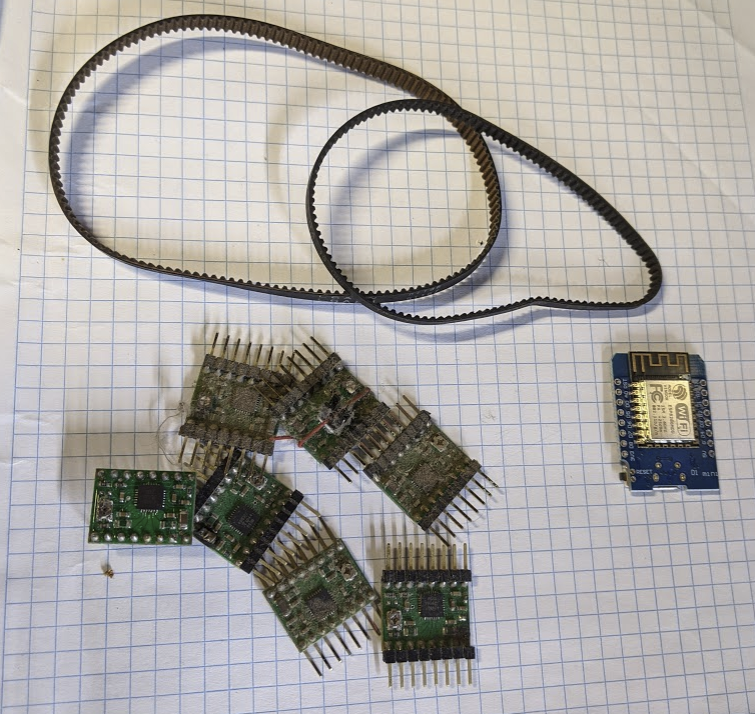

Salvaged belts, pololus and an ESP8266.

Salvaged belts, pololus and an ESP8266.

Note that these belts are actually S2M, not GT2, but they're both 2mm pitch, and I'm not going to be able to print pulleys that are meaningfully different with my 0.5mm nozzle.

So far the scrounge pile looks like:

| Item | Type | Count |

|---|---|---|

| Stepper motor | NEMA-17 1.8 steps/degree | 2 |

| Stepper driver | Pololu A4983 | 4 |

| Belt | S2M belt 120mm | 2 |

| Belt | S2M belt 230mm | 1 |

| Belt | S2M belt 278mm | 1 |

| Shafts | 8mm smooth stainless | 1 |

| Bearing | 608 | Many |

I probably won't be using all these parts.

What I want to accomplish next time

- Design and print the plastic parts.